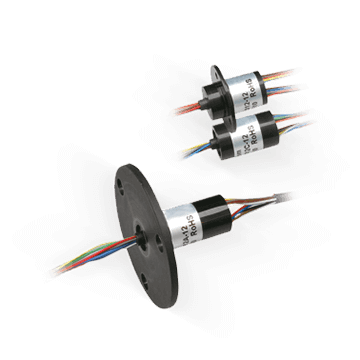

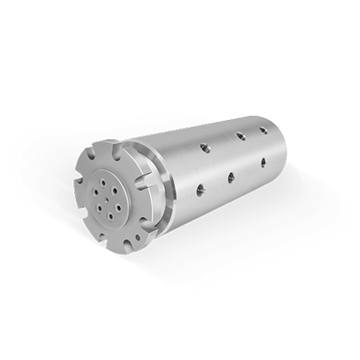

To achieve that, a rotating blade is used. It is made up of an electric resistance that heats the sealing blade and the temperature is monitored by a thermocouple temperature sensor embedded in the blade. A slip ring is then used in order to feed the electrical resistance and retrieve thermocouple signals between the rotating blade and the computer side.

Our Solutions

- Bin-picking applications

- Magnetic Handling Applications

- Modular EOAT

- Destacking/Thin Sheet Application

- Collaborative robots

Brands

Our product range

Support & Services

Our Solutions

- Packaging Machines Applications

- Medical/Parmaceutical Equipment

- Hose and Cable Reel Applications

- Multimedia and Entertainement Equipment

- General Industry Equipment

- Test Benches Applications

- Harsh Environment Applications

Brands

Our Solutions

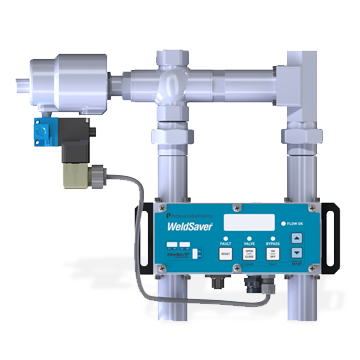

- Welding Process Applications

- Handling Applications

- Riveting/Gluing applications

- Vision or inspection applications

- Stamping line applications

Assemblies

Support & Services

Components

Slip ring are the best way to wire components that move. Indeed, cable carriers often induce cinematic constraints and low reliability thatSlip ring make disappear.

Low friction torque ofSlip ring mitigates the mechanical impact and continuous rotation capabilities make programming simpler.

Advantages

Benefits

Facts & Figures

Related industries

Rotation movement takes place at nearly every step of the process from bottle conveying to label placing. Sometimes, active components are embedded on a rotating plate and linked to the machine computer. Slip ring can perform this link while offering continuous rotation capabilities. Continuous rotation increase machine performance and reliability while easing the machine design.Slip ring can transfer all signal that can be met in such machines, motor power and control, sensors, field buses, etc.

Advantages

Benefits

Facts & Figures

Related industries

The common link, regardless of the final application, is the use of a Slip Ring or a Rotary Union. Cable reels usually transmit power and electric signals, data and different kind of fluids; instead, in case of high-frequency signals, high data rate or where a low bit error rate (BER) is required, the proper result is achieved with a fiber optic rotary joint. Our product range can cover nearly all application from power signals to high data rate or optical signals for cables and from pressurized air to hydraulic oil for rotary union.

Advantages

Benefits

Facts & Figures

Related industries

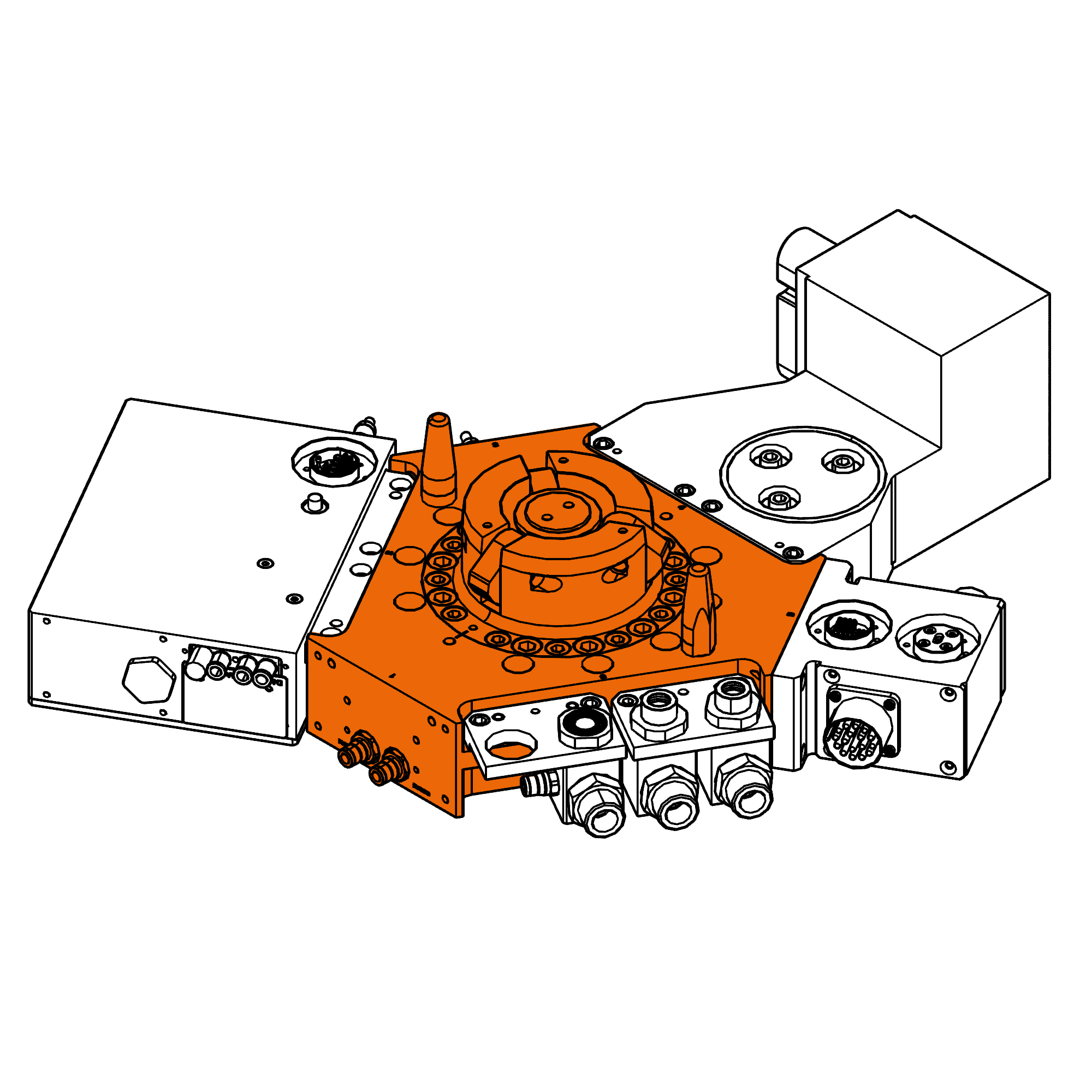

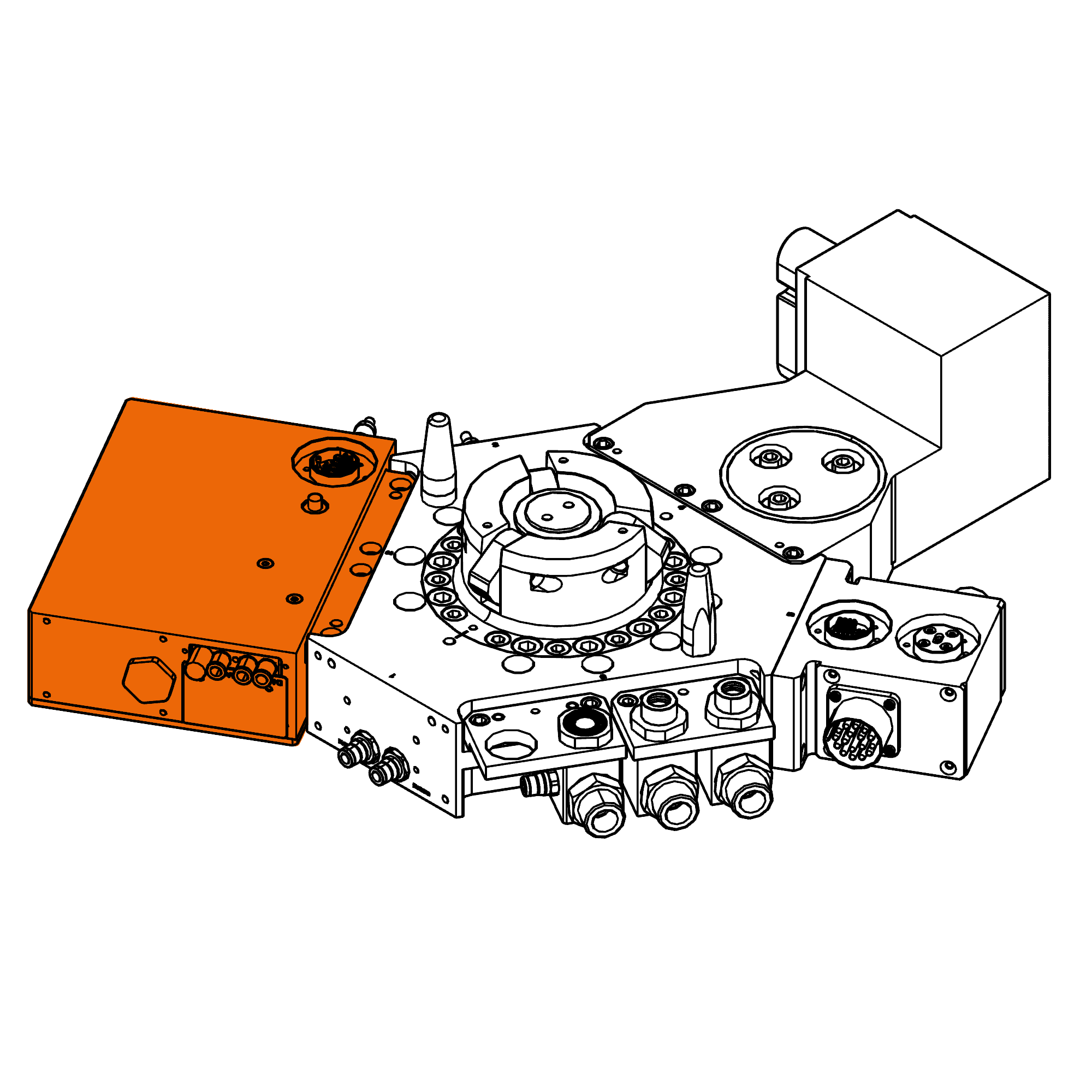

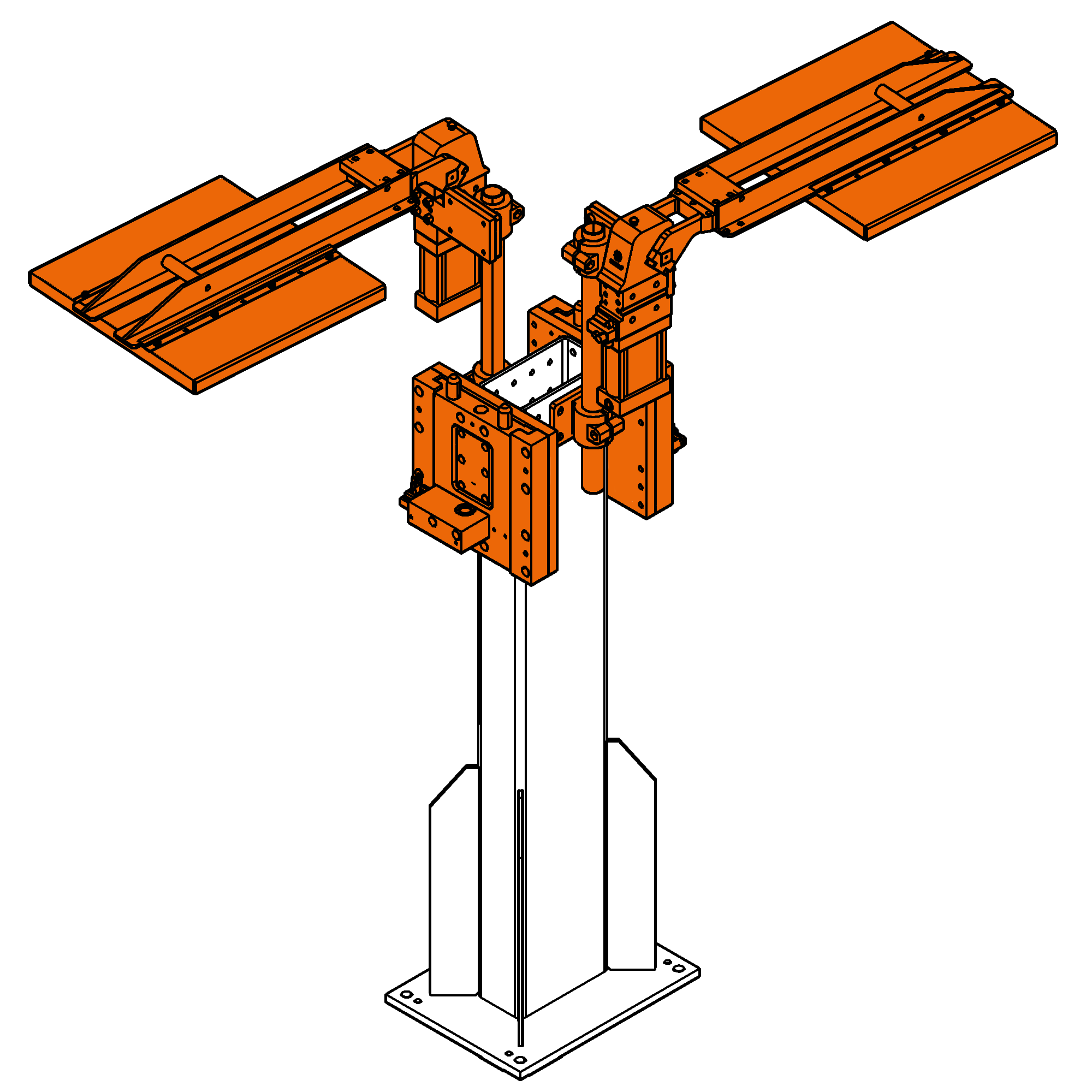

Those operations require special tooling that needs to be accurately handled and monitored with dedicated sensors in order to ensure repeatability. PES has already implemented tool changing systems for such special operations. Our custom module design and manufacturing capabilities help us to adapt to any kind of equipment that is present on the robot end-of-arm while the cam lock mechanism with integrated wear compensation ensure the accuracy and repeatability that riveting or gluing applications need.

Advantages

Benefits

Facts & Figures

Related industries

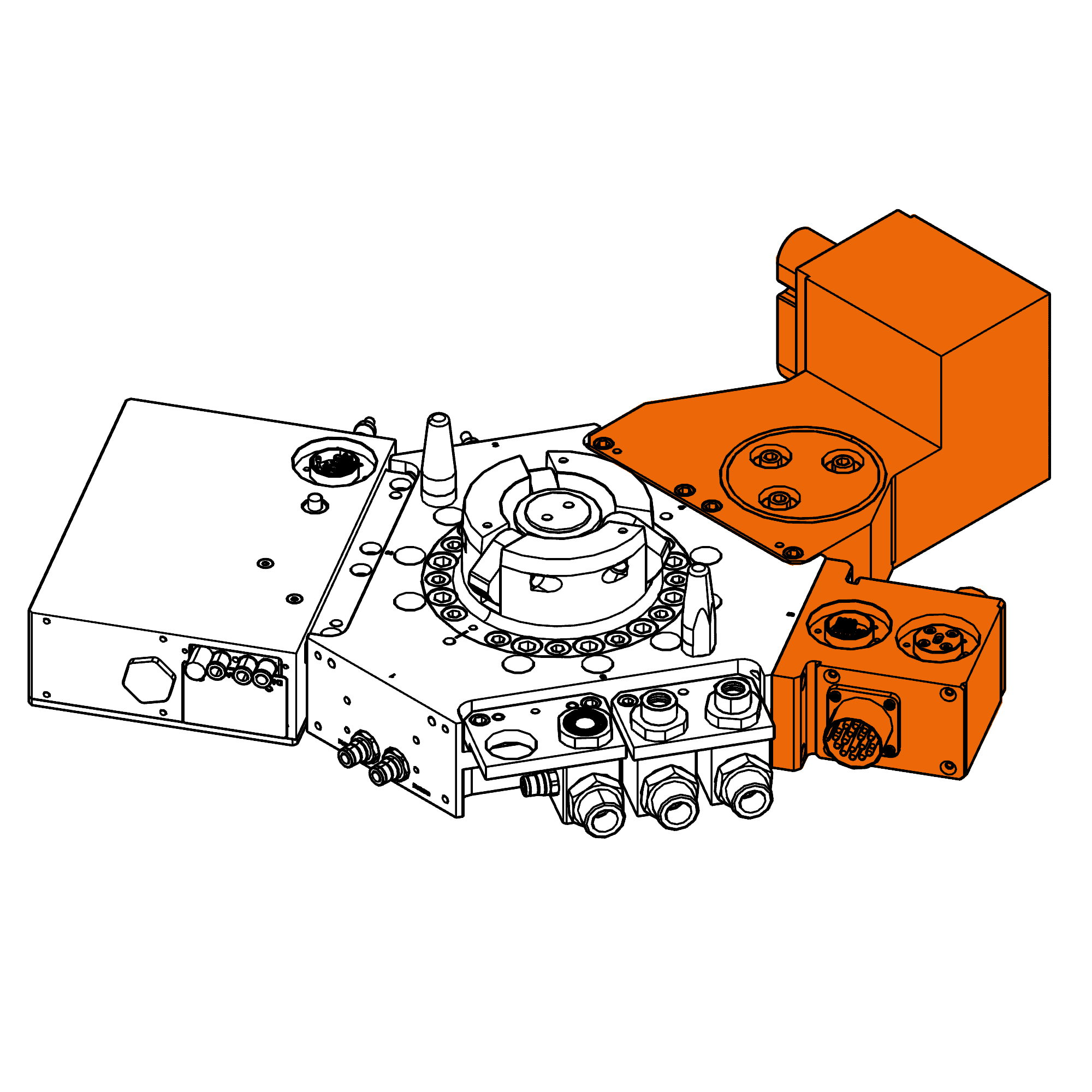

When using a tool changer with tools that embed such cameras, the major challenge is to transfer the high data rate video signal through the tool changer quick connection.

From standard 100Base-TX Ethernet to GigE Vision application, PES always provides the proper electrical interface to meet the communication standard requirement.

Sometimes we also integrate contact redundancy for increased availability of the video link.

Advantages

Benefits

Facts & Figures

Related industries

Product Engineering Services delivers specialized products that feature load bearing capabilities, stainless steel construction, and cross talk protection. By combining experience and the latest in quality control and manufacturing innovation, PES is able to provide dedicated solutions for the plastic production and processing industries such as plastic molding, injection molding, extrusion, blow molding, and rotary table integration.