Our Solutions

- Bin-picking applications

- Magnetic Handling Applications

- Modular EOAT

- Destacking/Thin Sheet Application

- Collaborative robots

Brands

Our product range

Support & Services

Our Solutions

- Packaging Machines Applications

- Medical/Parmaceutical Equipment

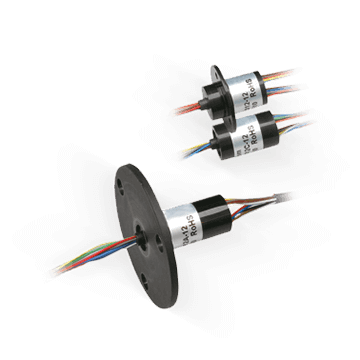

- Hose and Cable Reel Applications

- Multimedia and Entertainement Equipment

- General Industry Equipment

- Test Benches Applications

- Harsh Environment Applications

Brands

Our Solutions

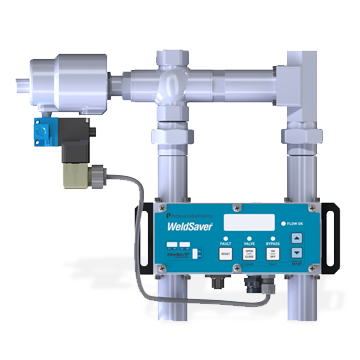

- Welding Process Applications

- Handling Applications

- Riveting/Gluing applications

- Vision or inspection applications

- Stamping line applications

Assemblies

Support & Services

Components

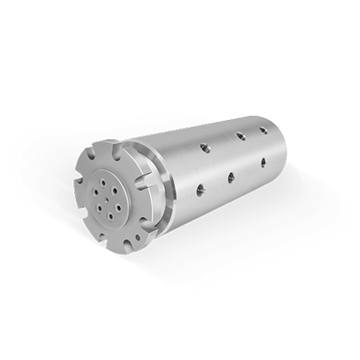

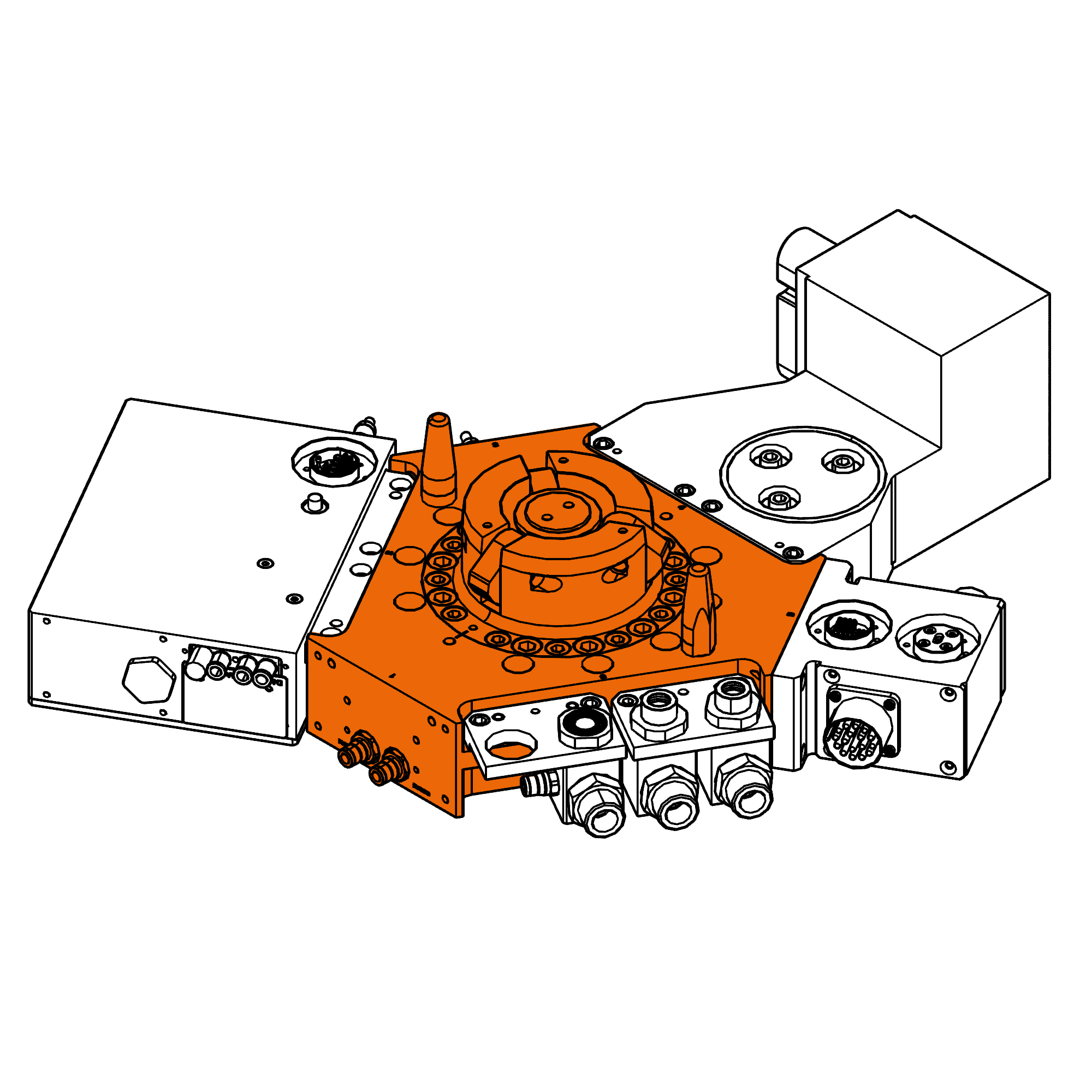

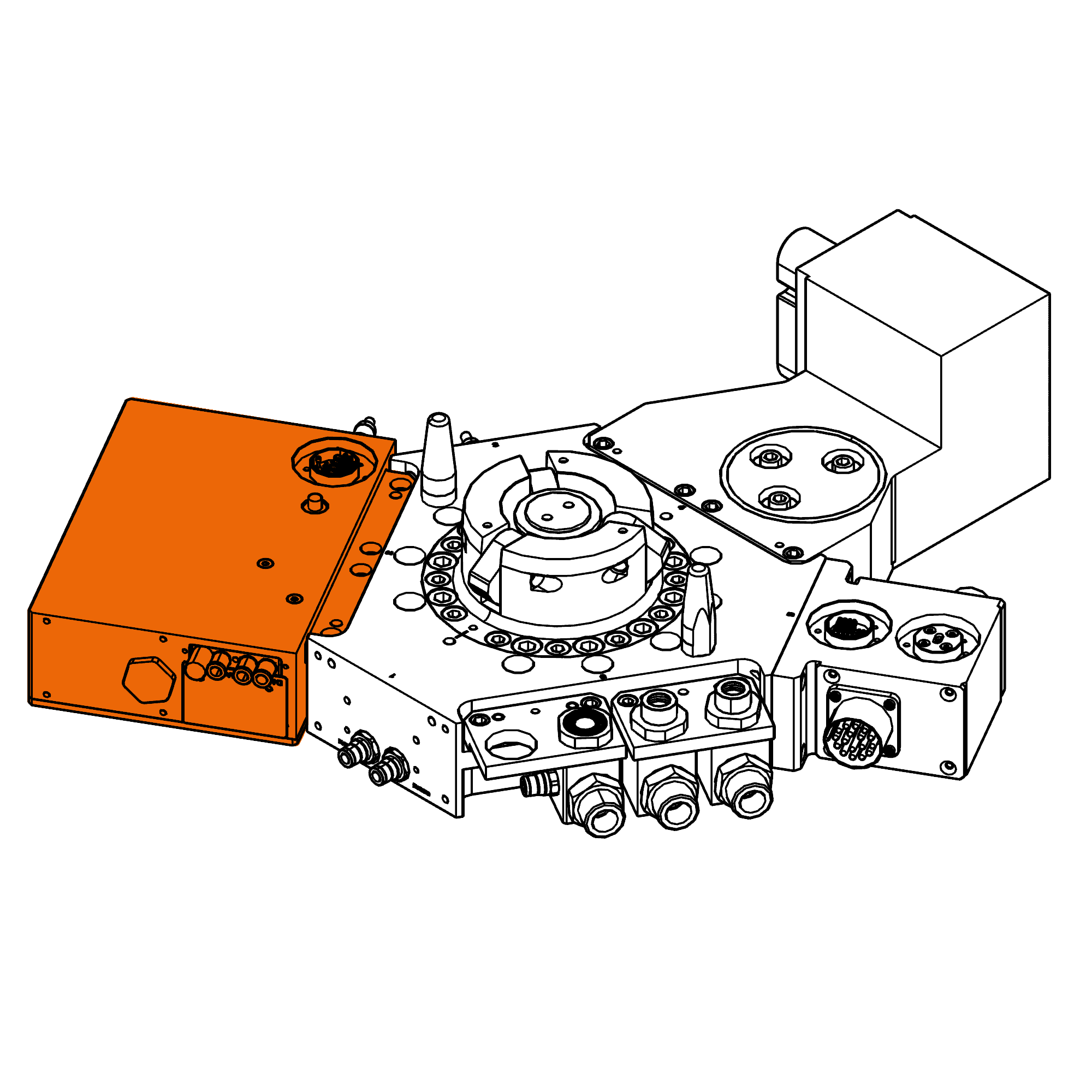

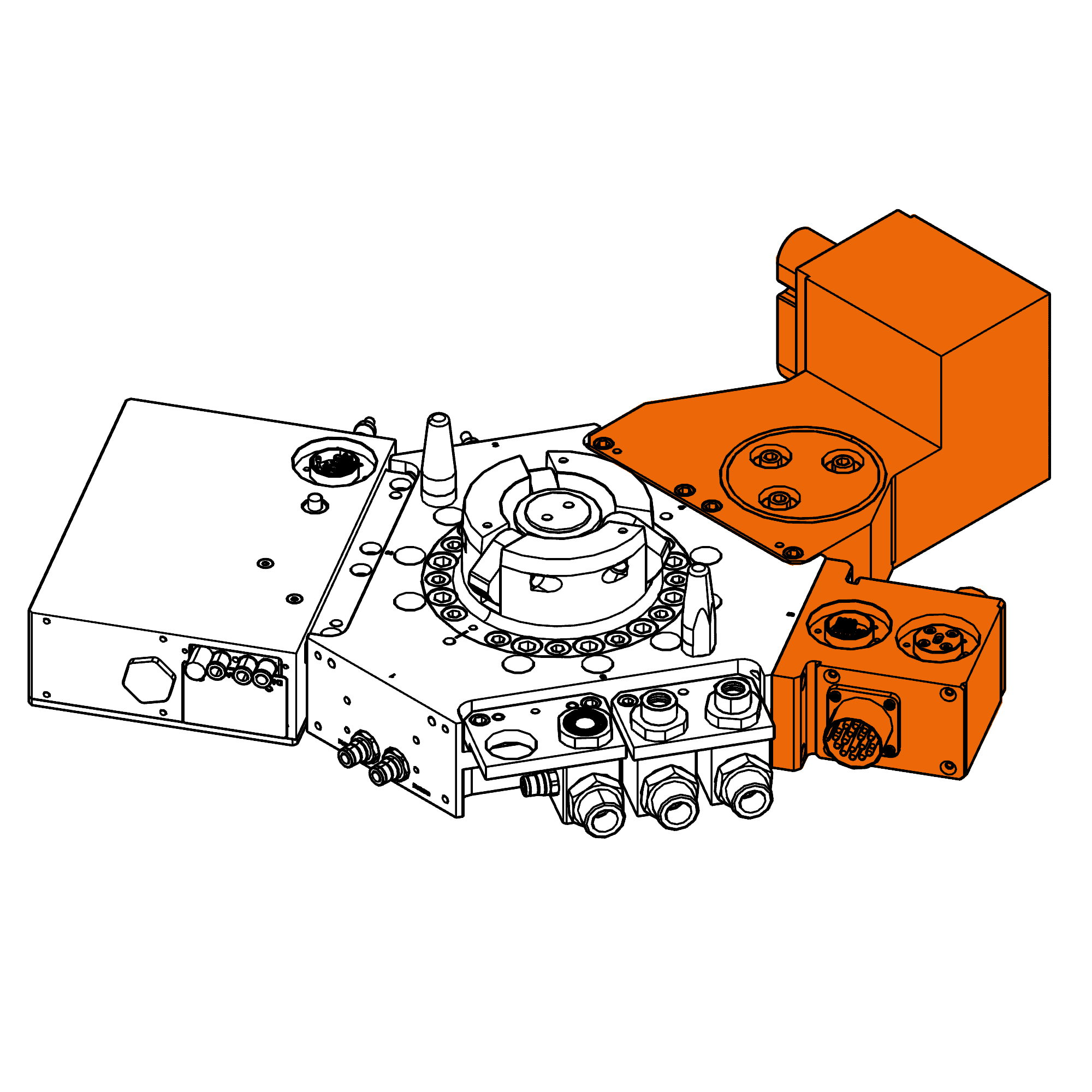

Ultrasonic inspection systems

Leveraging over 30 years of experience in spot weld inspection, we've developed PHAsis, a series of systems for both manual and automated spot weld checks using phased array ultrasound technology for high accuracy, particularly suited for the auto industry. PHAsis combines manual (PHAsisNEO) and automated (PHAsisBLU) inspections, allowing flexibility in choosing inspection modes. Results integrate seamlessly into clients' QA systems, enhanced by our expertise in material combinations and support for process integration and data optimization.

PHAsisNEOFor the manual inspection of spot welds

PHAsisNEO was specially developed for manual inspection of spot welds and longitudinal weld seams in production.

The focus is on very high inspection accuracy and a high level of usability for fast and reliable inspection. The color depth display of the spot weld as a D-scan by the phased array technology makes the spot weld quality “visible”. Due to the automatic evaluation suggestion and the imaging result display, the training effort is minimal.

4,95 kg

350 x 280 x 90 mm

IP64

0°C - 40°C

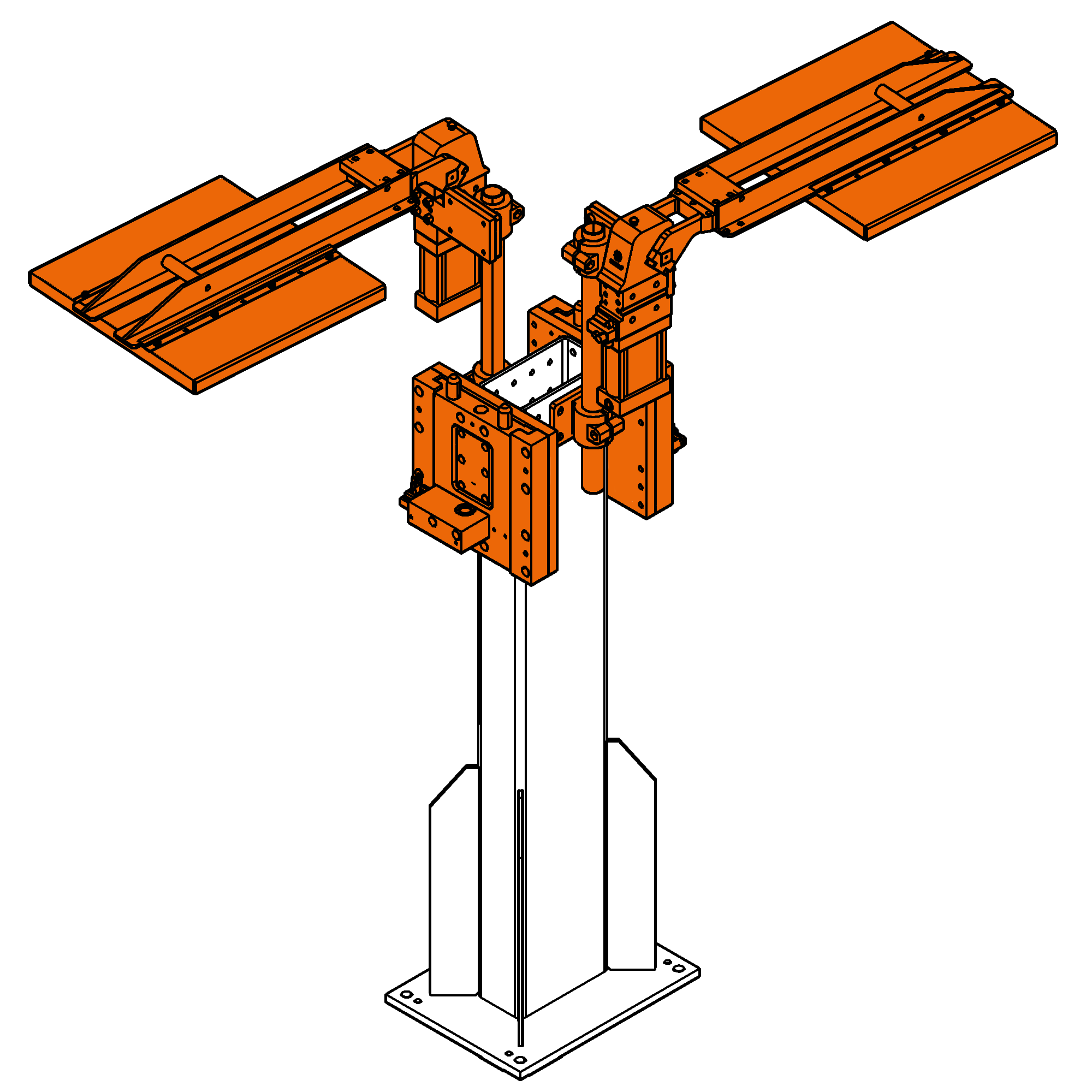

PHAsisBLUFor robot-controlled inspection of spot welds

PHAsisBLU was specially developed for the automated, robot-controlled inspection of spot welds and longitudinal weld seams: Fast & precise.

With the help of automated testing, significant savings potentials can be realized while at the same time achieving the best reproducibility of the measurement results. Here, man and robot work hand in hand. Inspection systems from the combination of PHAsisBLU and robot technology contribute to future-oriented quality assurance as well as to detailed documentation of the inspection results.