Safe, Reliable, Smart and Energy Efficient Gripping Tool

After some a period of trials and validation in the last few years, collaborative robots are now starting the be rolled-out in the industry. Alongside, a complete new range of dedicated product is appearing. Those new tools are properly designed in term of power and function for cobots applications.

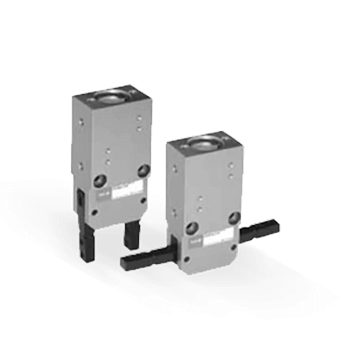

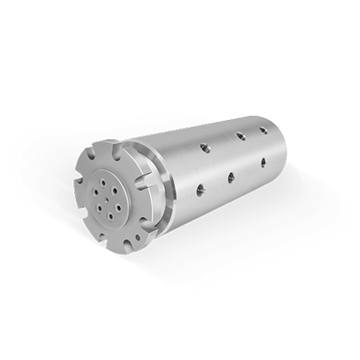

Among those new tools, once can find magnet grippers. They consist in a pneumatically or electrically actuated mobile magnet placed above a fixed one in order to activate an outer magnetic field that allows handling of ferrous parts while being extremely compact. Magnetic power is already installed in the product so the need for energy is minimal. And, unlike common preconception, residual magnetism of handled parts stays low.

Last important point for cobots but also industrial robots: safety. Our magnet gripper is intrinsically safe by design, once actuated it does not need any source of energy to keep its ON position. Parts transfer with this gripper can then occurs without energy, actuation can be performed at a fixed station at the start and arrival of the process.

This technology is quite empirical, tool dimensioning then needs experience-based expertise which PES can offer. Do not hesitate to contact us for your next project. The offered power range is quite large and those units can equip the smallest collaborative robot as well as the larget industrial one.

Key Features

- Highly capable tools, large product range

- High duty cycle to support production flow needs

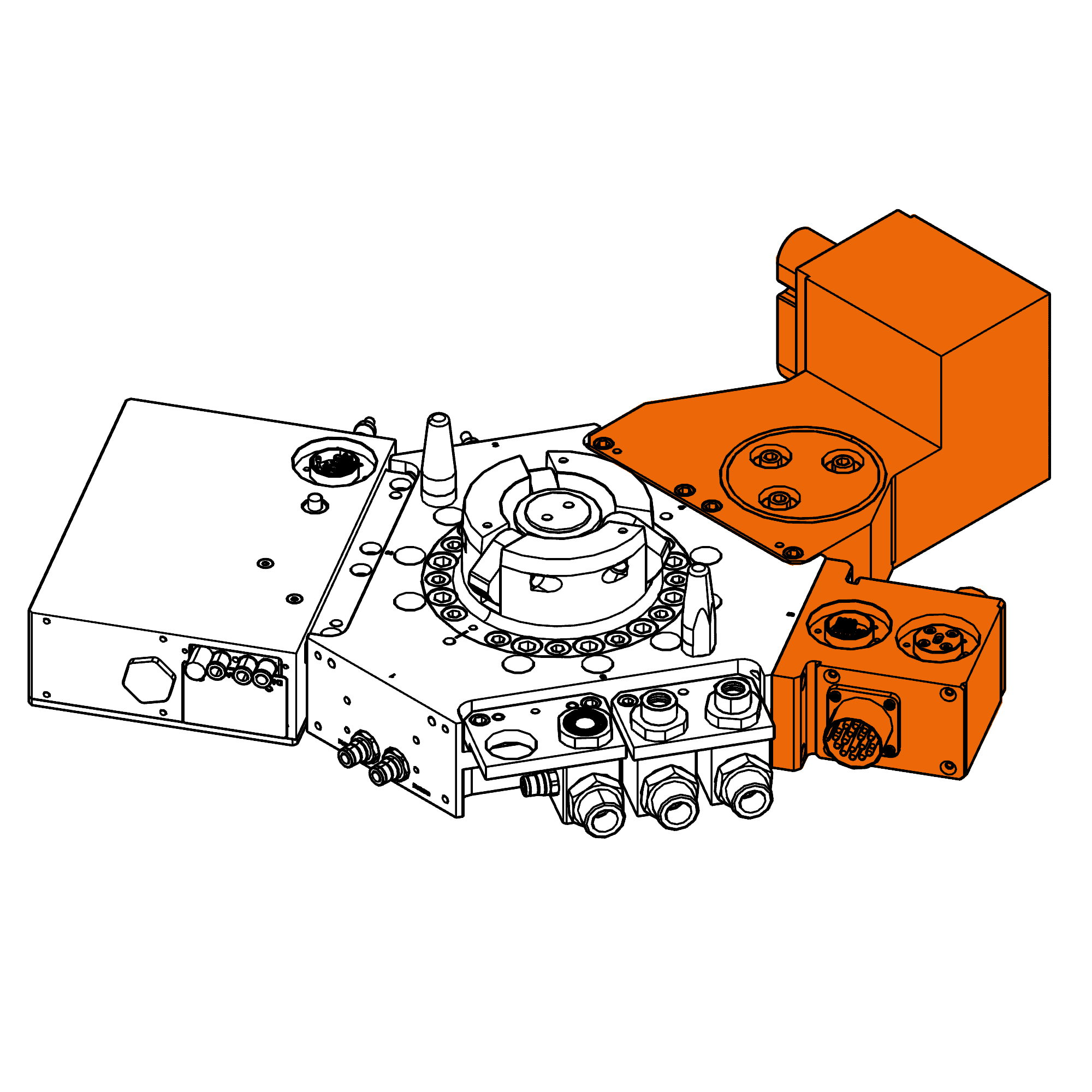

- Smart capabilities and electrical actuation available

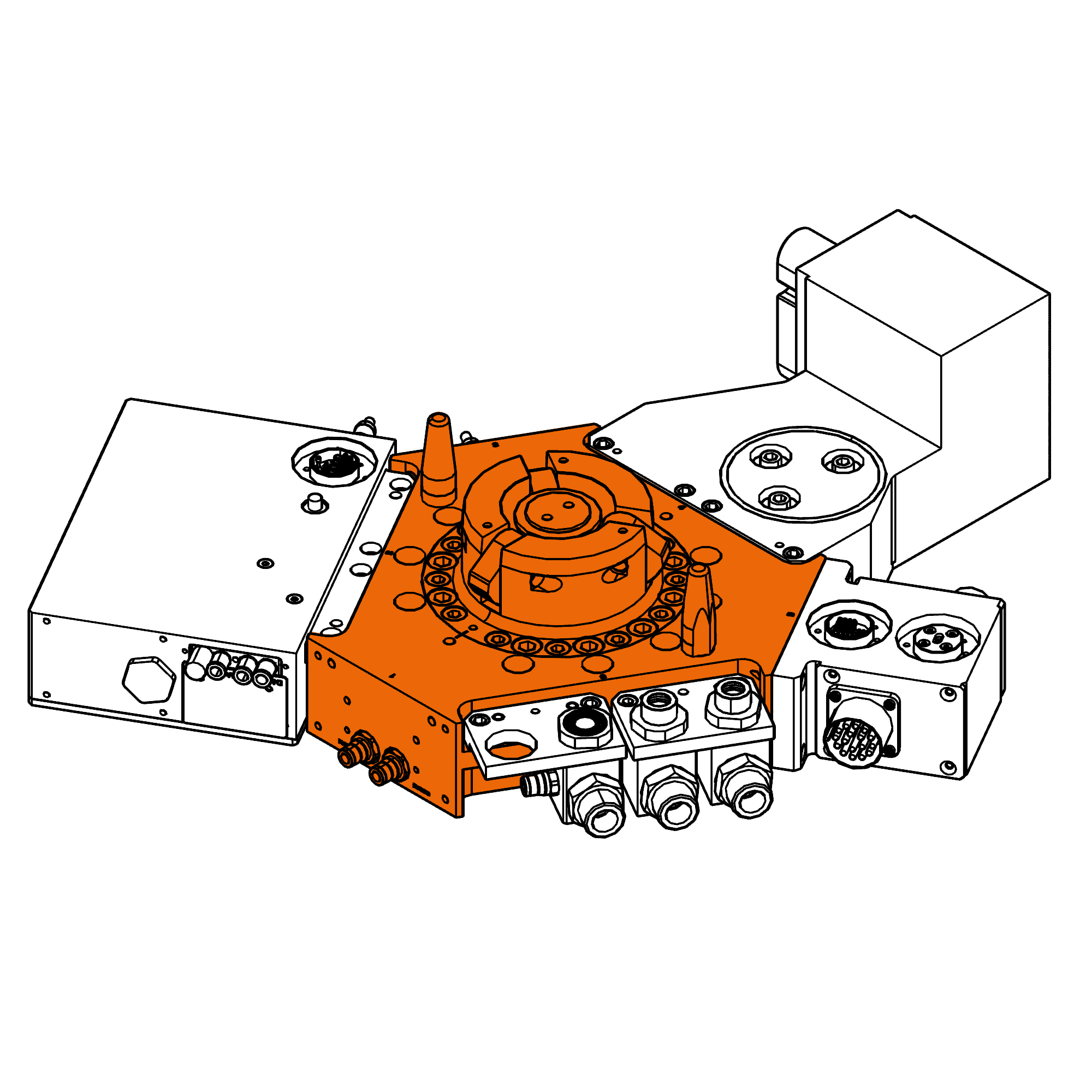

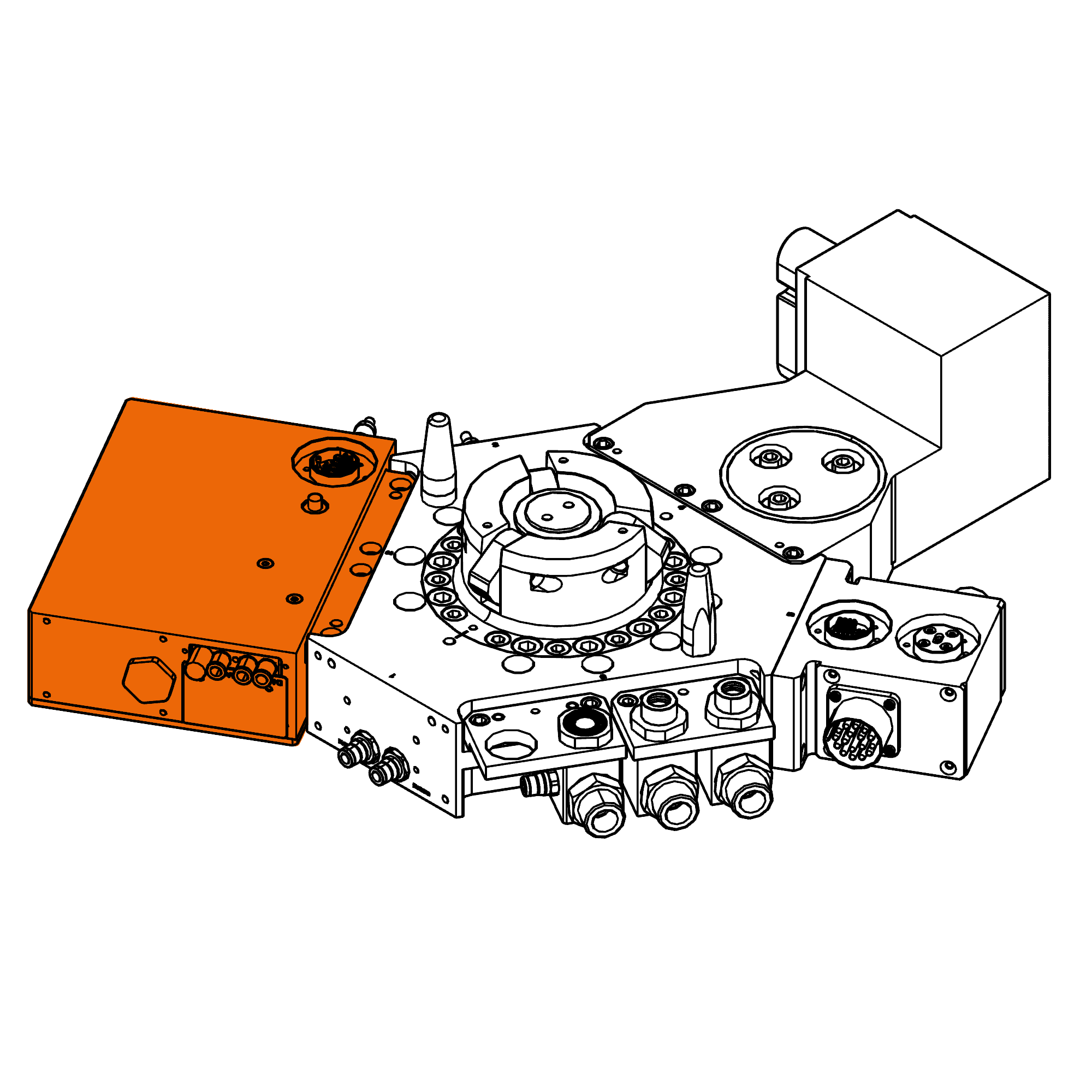

- Can be encapsulated in protective housing

PES Support Outcomes

- Tool dimensioning and selection

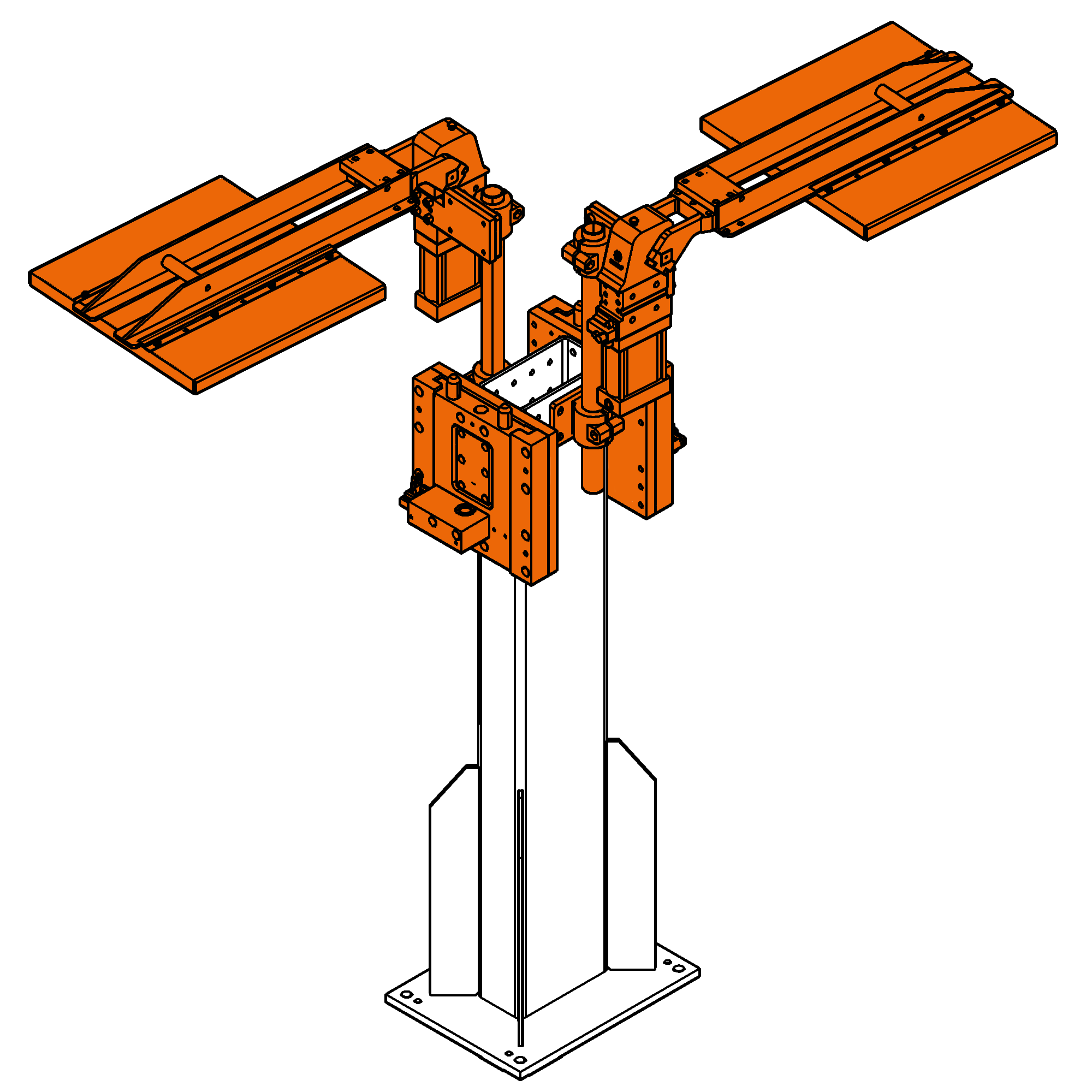

- Complete EOAT design capabilities (structure, function, calculation, electrical/pneumatical équipment)

- Design and realization of custom or standard compliant mounting support

- Feasibility and validation tests performed on a robot at PES lab

Advantages

- Multiple gripping options on the same EOAT

- Fail-safe

- Energy Efficient

- No external hazardous movement

Benefits

- Mitigate the use of complex grippers or tool changer

- Low power needed

- Easy integration and programming

Facts & Figures

- Magnet field actuation time is measured in milliseconds

- Lifetime can reach 9 million of operation cycles depending on gripping conditions and integration quality

- Handling issue fixed, tested and realized by PES