Our Solutions

- Bin-picking applications

- Magnetic Handling Applications

- Modular EOAT

- Destacking/Thin Sheet Application

- Collaborative robots

Brands

Our product range

Support & Services

Our Solutions

- Packaging Machines Applications

- Medical/Parmaceutical Equipment

- Hose and Cable Reel Applications

- Multimedia and Entertainement Equipment

- General Industry Equipment

- Test Benches Applications

- Harsh Environment Applications

Brands

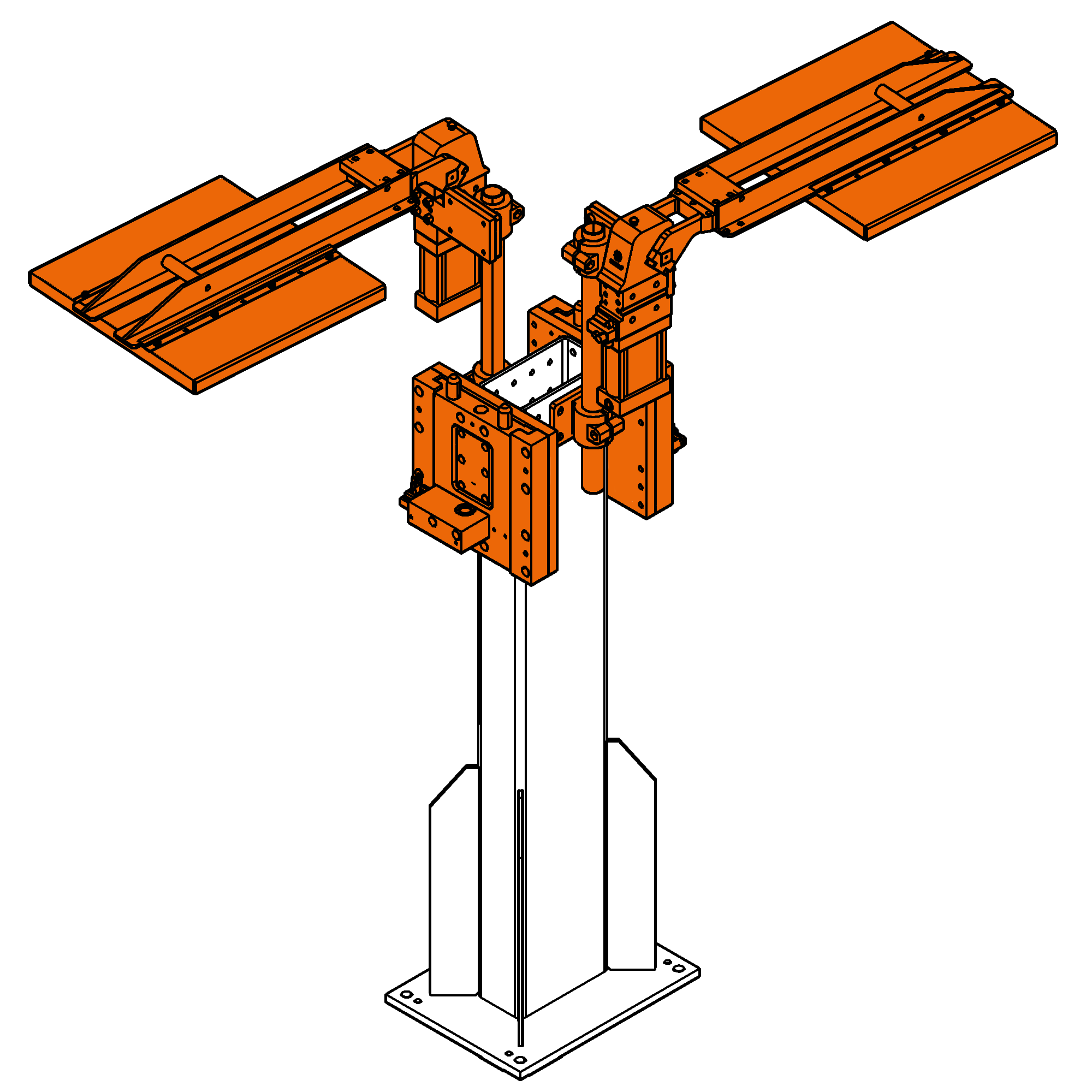

Our Solutions

- Welding Process Applications

- Handling Applications

- Riveting/Gluing applications

- Vision or inspection applications

- Stamping line applications

Assemblies

Support & Services

Components

Swivel Connexions and Motion Control Solutions

A catalog for all your applications

Solutions for:

ROV

ROVs and drones, which are now quite common for exploring extreme environments, are equipped with micromotors operating their various actuators and propellers requiring high reliability and lifetime. Some specific applications may use slip rings for a real-time and reliable power or communication link (fiber, data bus)

ROV

ROVs and drones, which are now quite common for exploring extreme environments, are equipped with micromotors operating their various actuators and propellers requiring high reliability and lifetime. Some specific applications may use slip rings for a real-time and reliable power or communication link (fiber, data bus)

Cable/hose reels

Cable and/or hose reels are essential elements for the distribution of electrical signals or fluid power supplies. They are often equipped with slip rings or robust rotary joints. Fluids and electrical signals can also be combined in hybrid solutions.

Radars and sensors

PES has electrical expertise to provide solutions adapted to sensitive applications such as radars or other sensors. Our slip rings offer a competitive and reliable solution.

Automated sails

The decarbonization of maritime transportation requires the re-invention of wind propulsion. Today, the new generation sails embed a series of equipment and increasingly automated. Slip rings and rotary joints allow them to drive these sails according to wind direction without taking into account the mechanical constraints of the cables.

Lighthouse

Typical application of slip rings, a rotating electrified light source. Lighthouses are a good example. PES has (electrical and mechanical) the skills to help you in your integration project.

Antennas

As for radars, the slip rings are quite common in this field. They allow free rotation while transferring very sensitive signals in sometimes harsh environments.

Military equipment

Our slip rings and rotary joints can meet the highest demands. Our mechanical production and harness assembly capabilities meets the IPC-620A quality standard and allow us to offer complete solutions that can be directly integrated in customer’s equipment.

Wind or tidal turbines

In one direction or the other, our slip rings ensure the transfer of electrical signals. In the case of wind turbines, they allow the transmission of power from the nacelle to the mast or the transfer of control signals from the mast to the mobile elements of the nacelle and/or the blades.

Medical equipment

Micromotors and slip rings are very present in the medical field, whether in micro or macro equipment. Compact, reliable, and robust, they will meet the expectations of various applications, from the laboratory to the surgical suite.

Packaging machines

Packaging machines use rotary kinematics for various reasons. Often, they need to transfer pressurized air for the moving pneumatic clamping elements and electrical signals to power the automation equipment and the various motors or actuators. With our products (micromotors and hybrid rotary joints), we support OEMs or end-users of special packaging machines. We can offer technical support, mechanical integration capabilities and wiring services.

AGV

AGVs are increasingly present in the industry, platforms are multiplying to meet different needs. Our micromotors and slip rings can be perfectly integrated thanks to their robustness and compactness.

Civil engineering

Civil engineering machines are becoming more complex to perform specific tasks. They can embed advanced technologies such as vision sensors or servomotors. The rotary union and slip rings offered by PES can be adapted to the mechanical constraints of these machines in order to transmit signals and energies freely and reliably.

Master motion, optimize performance. With PES S.A., motion control expert and Servotecnica, Flux, Rotaseal and DSTI partner, benefit from precision solutions for your industrial applications: micromotors, encoders, slip rings, and hybrid systems. Reliability. Precision. Seamless integration.

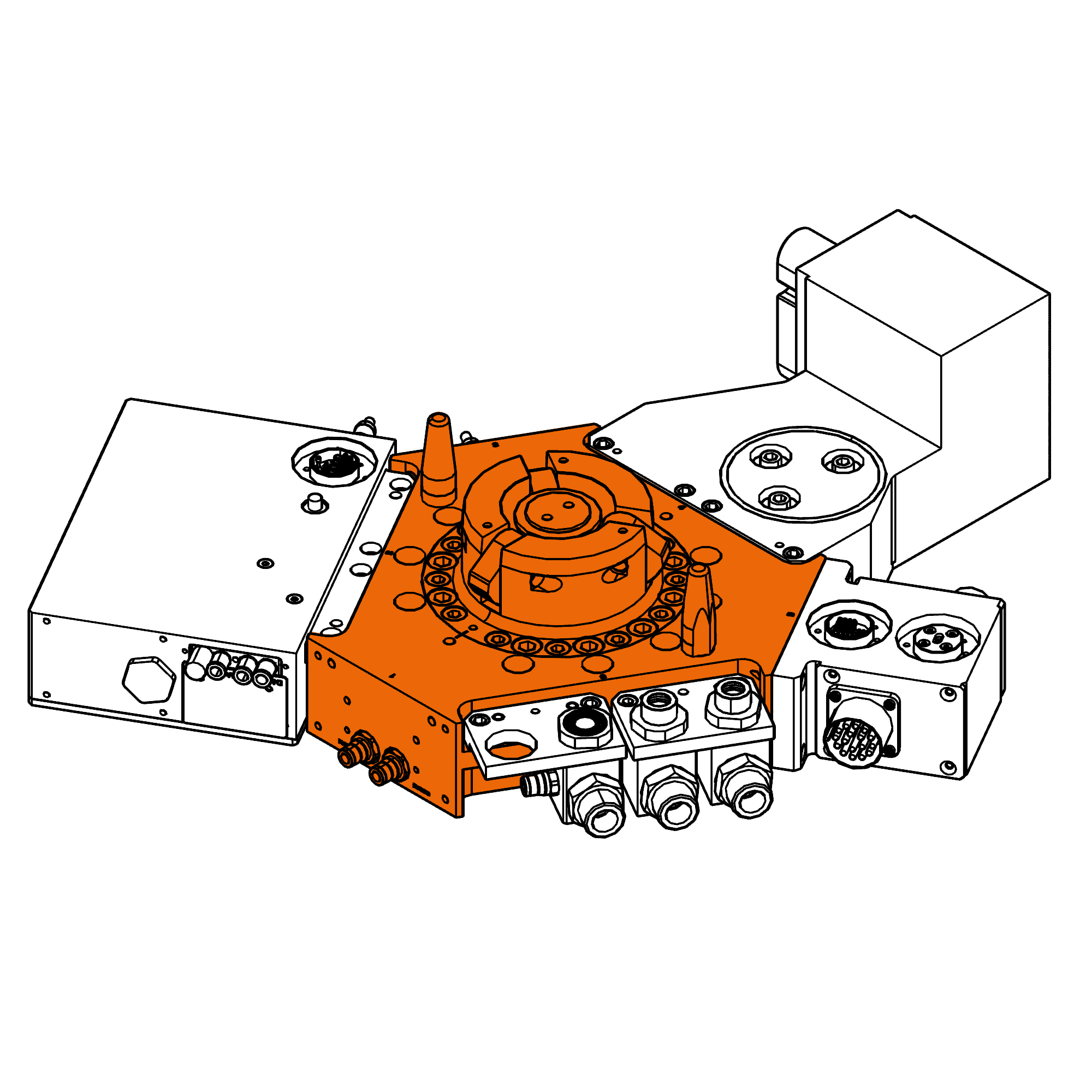

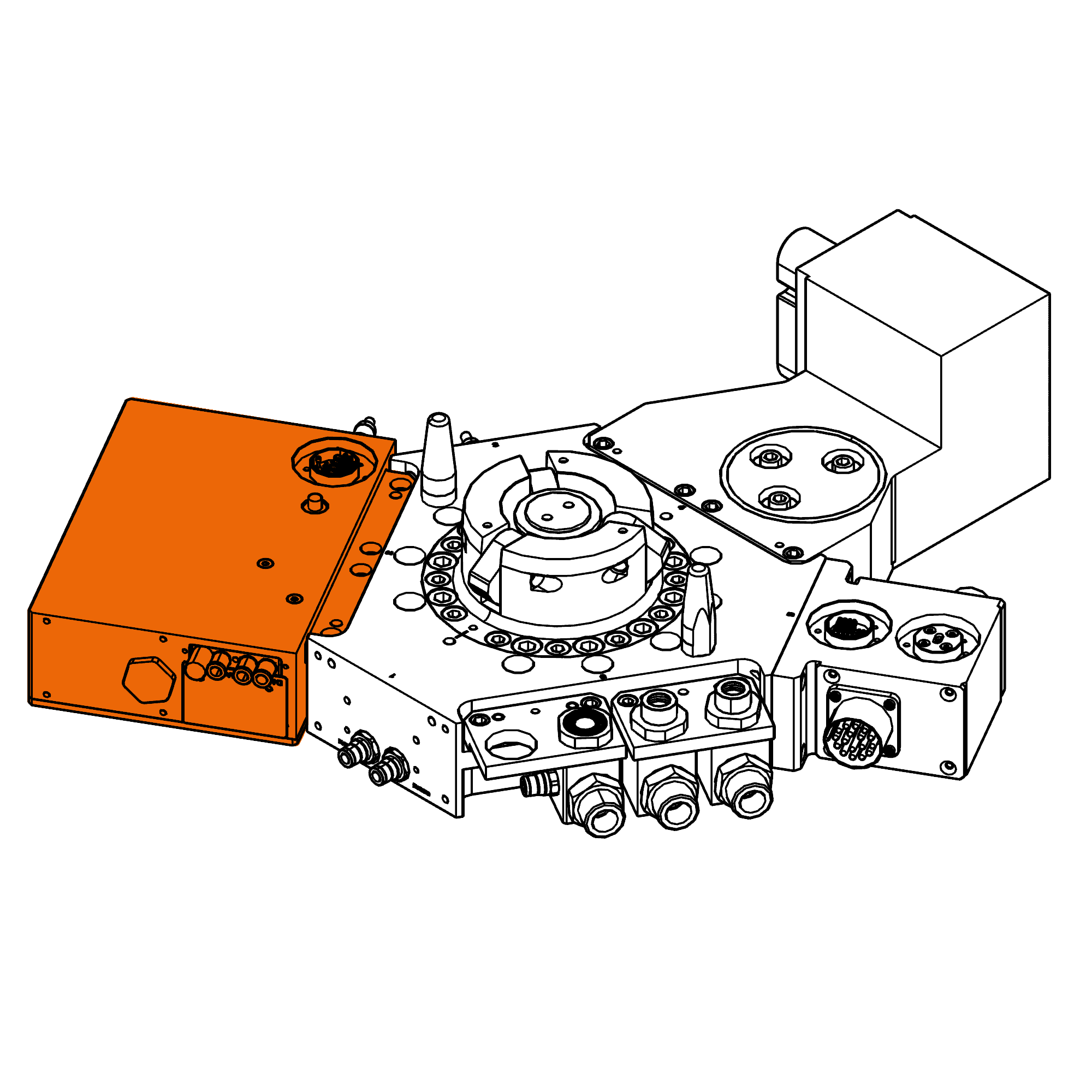

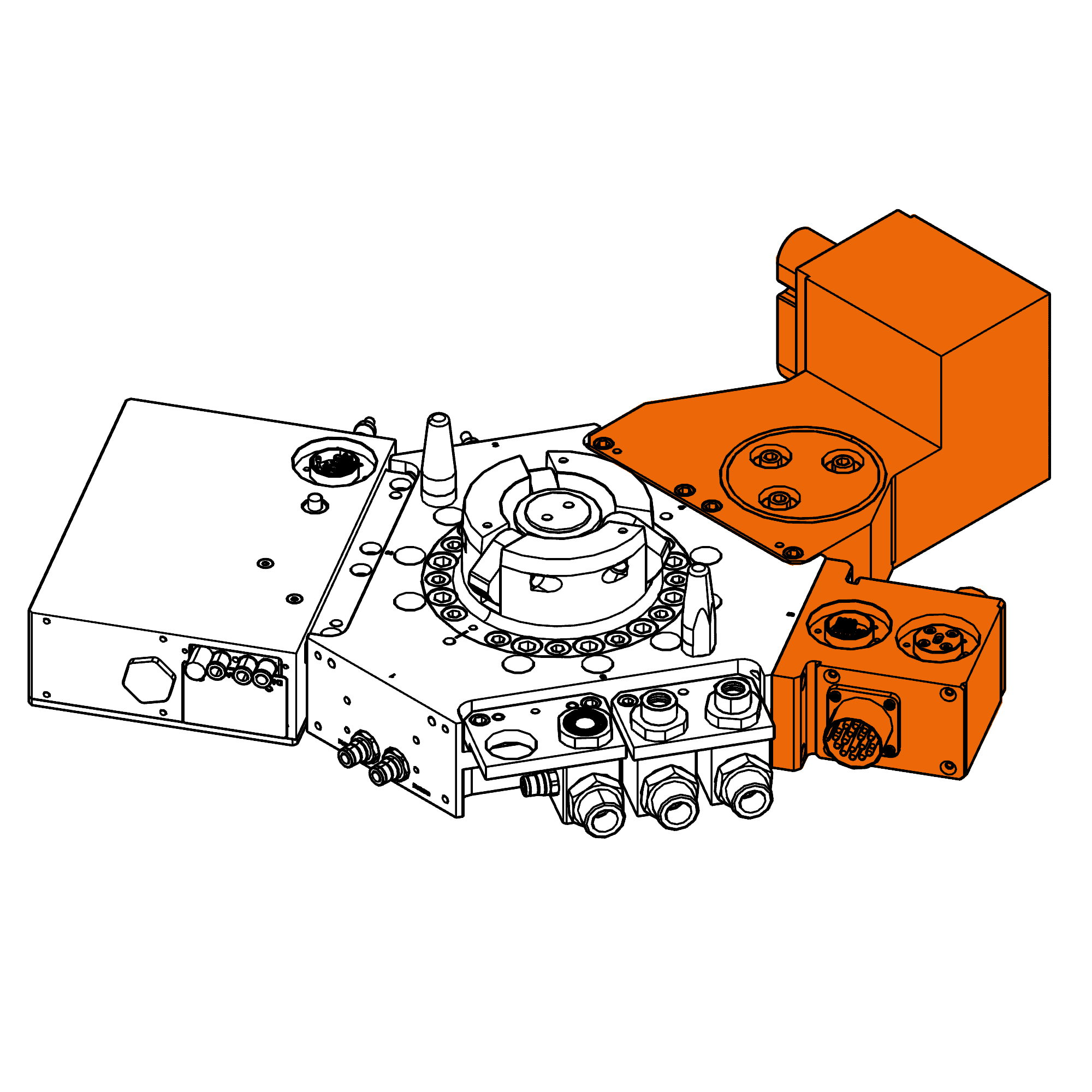

Technology, performance and adaptability

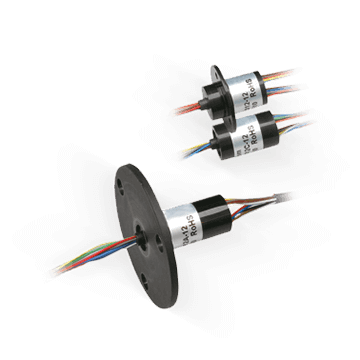

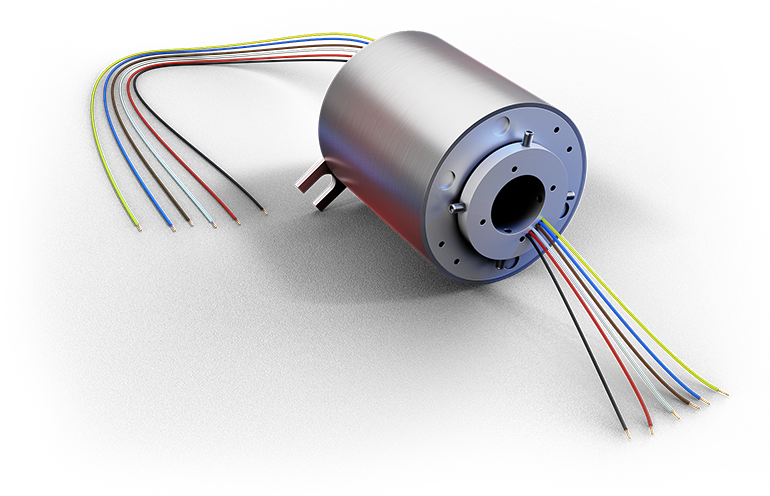

Servotecnica slip rings combine innovation and robustness thanks to a modular architecture and high-quality components.

Our product ranges cover all industrial needs:

- SVTS series (A to E) for electrical and hybrid applications

- Hollow shaft versions for the passage of fluids, cables, or shafts

- Flat and compact solutions for embedded systems

- Custom models integrating signals, power, Ethernet, or compressed air within a single module.

Certified to industrial standards, and supported by local technical assistance provided by PES S.A. in Belgium.

We support each client from the definition of requirements to final integration to ensure a solution perfectly adapted to your mechanical, electrical, and environmental constraints.

PES S.A. – Reliability in rotation.

Slip rings

Mastering Motion Expertise

Rotational reliability, continuous performance.

Servotecnica slip rings, distributed and integrated by PES S.A., are designed to ensure uninterrupted transmission of electrical signals, power, data, and fluids between stationary and rotating structures.

With over 35 years of experience in motion control and industrial connectivity, our solutions meet the demands of the most challenging environments: robotics, automation, energy, testing, medical, food processing, and industrial packaging.

Every rotation becomes a promise of stability, precision, and durability, ensuring optimal system operation with minimal maintenance.

Swivel Connexions and Motion Control Applications

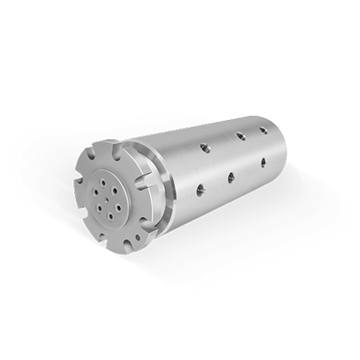

Rotary unions

Excellence in Rotary Transfer

Reliable transfer of energy and fluids.

The rotary unions distributed by PES S.A. are designed to ensure smooth, reliable, and continuous transfer of liquids, compressed air, or hydraulic oils between stationary and rotating structures.

These high-quality solutions guarantee performance and safety in industrial systems where transfer precision is critical: robotics, tooling, packaging, energy, offshore, and test benches.

Engineered for high-pressure, high-speed, or critical environments, DSTI and Rotaseal rotary unions deliver leak-free sealing, exceptional durability, and maintenance-free operation.

Their modular design and robust construction make them a trusted choice for OEMs and system integrators seeking proven, reliable solutions.

PES Rotary Unions: Performance and Precision

The rotary unions offered by PES stand out for their cutting-edge engineering, high machining precision, and ability to handle high pressures and flow rates. Available in single or multi-channel versions, they enable the simultaneous transmission of multiple fluids without interference.

In collaboration with PES S.A., these technologies can be integrated into systems that combine fluid transfer, electrical signals, Ethernet, or power within hybrid interfaces.

Each solution is tested, validated, and certified according to industrial standards, and benefits from the technical expertise of PES S.A., supporting clients from model selection through to commissioning.

Controlled performance, integrated by PES.

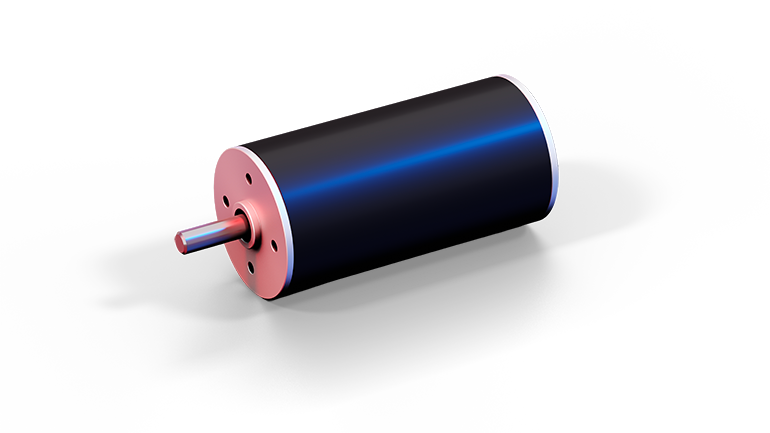

Micromotors

Miniature precision

serving industrial performance

Servotecnica micromotors, distributed by PES S.A., embody the excellence of precision motion control.

Designed to offer maximum efficiency in a minimal footprint, they combine advanced technology, reliability, and motion mastery to meet the demands of the most challenging applications.

Available in brushless and coreless versions, these motors ensure smooth, quiet, and long-lasting operation, even in complex industrial environments. Brushless models stand out for their high efficiency, low heat generation, and long service life, making them ideal for systems requiring continuous operation and minimal maintenance. Coreless versions offer exceptional responsiveness, low inertia, and precise instant torque, ensuring ultra-fine motion without vibrations or jerks.

Thanks to their compact and modular design, Servotecnica micromotors integrate easily into light robotics, precision automation, medical devices, optics, and inspection and measurement systems.

When combined with encoders, planetary gearboxes, or electronic drivers, they form a complete motion control solution, optimizing every movement with precision and consistency.

With its expertise in integration and industrial engineering, PES S.A. supports each client in the selection, configuration, and validation of the most suitable solution.

Each motor is tested, calibrated, and certified according to the strictest European standards, ensuring consistent quality and proven long-term durability.

Servotecnica Micromotors – the power of motion, at the scale of precision.

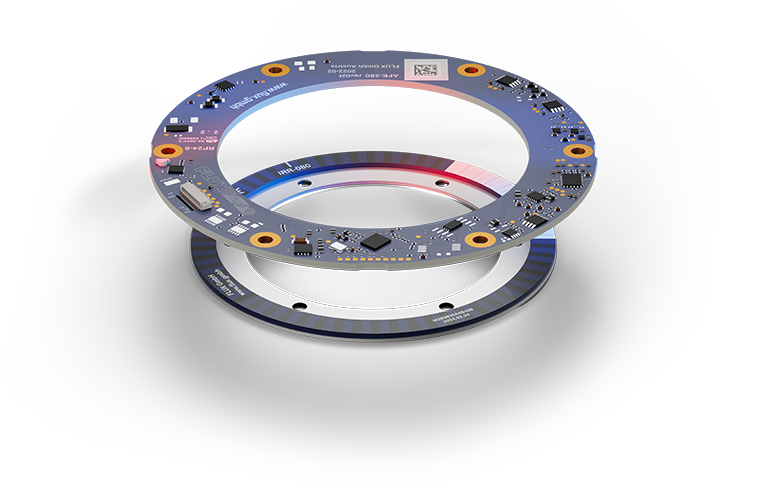

Coders

Measuring motion with extreme precision

FLUX GmbH encoders, distributed by PES S.A., offer unmatched reliability in position and speed measurement.

Designed to meet the most demanding motion control requirements, they combine cutting-edge technology with industrial robustness to ensure absolute precision, even under harsh conditions.

Thanks to a contactless design, FLUX encoders provide high electromagnetic immunity (EMC), vibration resistance, and exceptional durability. They are perfectly suited for demanding environments such as robotics, wind power, automation, machine tools, defense, or energy production.

Each sensor is developed with an obsession for signal stability and measurement accuracy, ensuring reliable angular and linear positioning, cycle after cycle.

FLUX Technology and PES S.A. Expertise

The FLUX range includes various measurement technologies such as magnetic encoders, high-resolution optical and contactless inductive systems, offering accuracy down to the arc-second.

Their modular design allows easy integration into brushless motors, robotic axes, rotary tables, or multi-axis control systems. FLUX encoders stand out for their exceptional EMC immunity, consistent repeatability, and ability to operate without recalibration in environments subject to thermal or mechanical variations.

As a technical partner of FLUX GmbH, PES S.A. handles the selection, integration, and validation of each encoder according to your specific needs. Our expertise covers mechanical and electronic compatibility, interface customization (SSI, BiSS, TTL, analog, Ethernet), and full commissioning.

Each encoder is tested, calibrated, and certified according to European quality standards, ensuring reliable, stable, and long-lasting measurements.

FLUX GmbH Encoders – German precision, integrated by PES S.A.

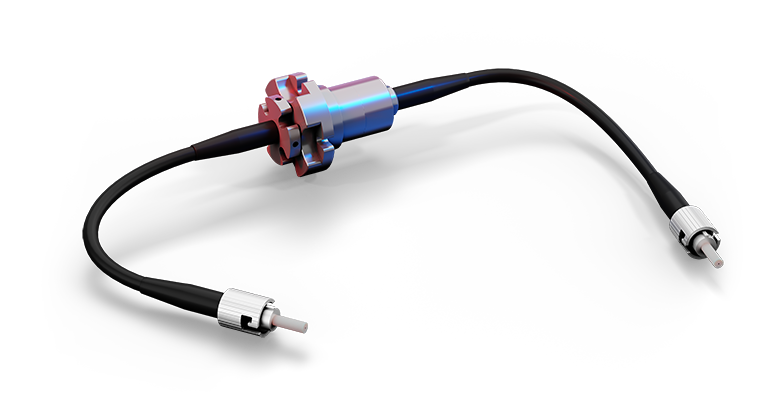

FORJ(Fiber Optic Rotary Join)

Transmission optique continue, sans perte de signal

Les Fiber Optic Rotary Joints (FORJ) assurent la transmission ininterrompue de signaux optiques entre des parties fixes et rotatives, tout en préservant la qualité et l’intégrité du signal.

Conçus pour des environnements à forte exigence de performance, ils garantissent un débit constant, une bande passante élevée et une immunité totale aux interférences électromagnétiques (CEM).

Les FORJ sont utilisés dans une grande variété d’applications : systèmes vidéo HD, antennes radar, tests électromécaniques, robotique, télécommunications, défense ou énergies renouvelables.

Leur conception compacte et robuste en fait une solution fiable et durable, même dans les environnements soumis à des vibrations, variations thermiques ou charges dynamiques élevées.

Chaque rotation reste stable, précise et sans perte — une garantie de performance optique et mécanique sur la durée.

Les FORJ Servotecnica, intégrés et distribués par PES S.A., sont disponibles en versions monovoie ou multivoies, selon le type et le volume de données à transmettre. Leur architecture optique de haute précision assure un alignement parfait entre les fibres, minimisant les pertes d’insertion et garantissant une continuité du flux lumineux, même à haute vitesse de rotation.

PES S.A. va plus loin en proposant des solutions hybrides personnalisées, combinant les FORJ à d’autres technologies :

- Circuits électriques pour signaux ou puissance

- Voies pneumatiques ou hydrauliques

- Transmission Ethernet ou data bus industriels

Ces modules multi-énergie permettent de centraliser la connectique rotative au sein d’une interface unique, compacte et optimisée pour chaque application.

En tant que partenaire technique Servotecnica, PES S.A. accompagne chaque projet depuis la sélection du FORJ, la personnalisation mécanique et optique, jusqu’à la validation finale dans votre système.

FORJ Servotecnica – la lumière au cœur du mouvement, intégrée par PES S.A.

Customization

Contact us for your project

At PES S.A., we go beyond simply distributing components.

We customize and hybridize our products — slip rings, rotary unions, micromotors, encoders, and FORJs — to design complete, precise interfaces tailored to each application.

Our goal: to offer each client a unique solution optimized to their mechanical, electrical, fluidic, or communication constraints, ensuring performance, reliability, and perfect integration into their industrial environment.