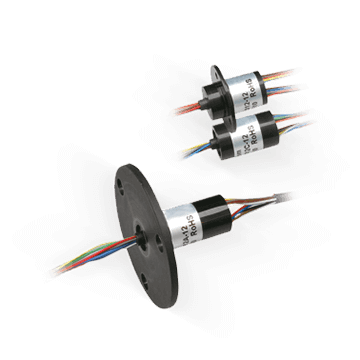

Light Control and Power in the same Capsule Slip Ring

Moving head projectors are more and more used in theatres and shows. These devices must be resistant and extremely flexible and so able to solve all kind of problems faced by lighting engineers on a daily basis. For this reason, these projectors are equipped with a wide range of motors to maneuver them when quiet, smooth and high-speed movements, such as the ones of tilt, pan, and focus, are required.

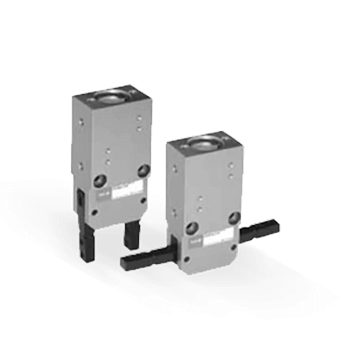

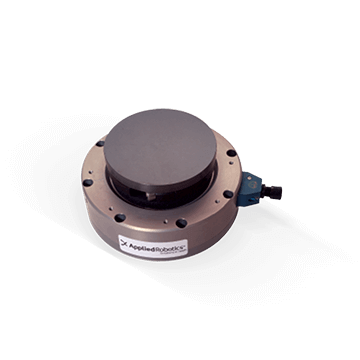

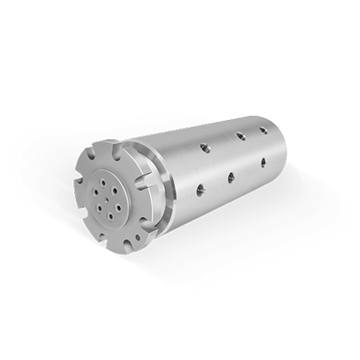

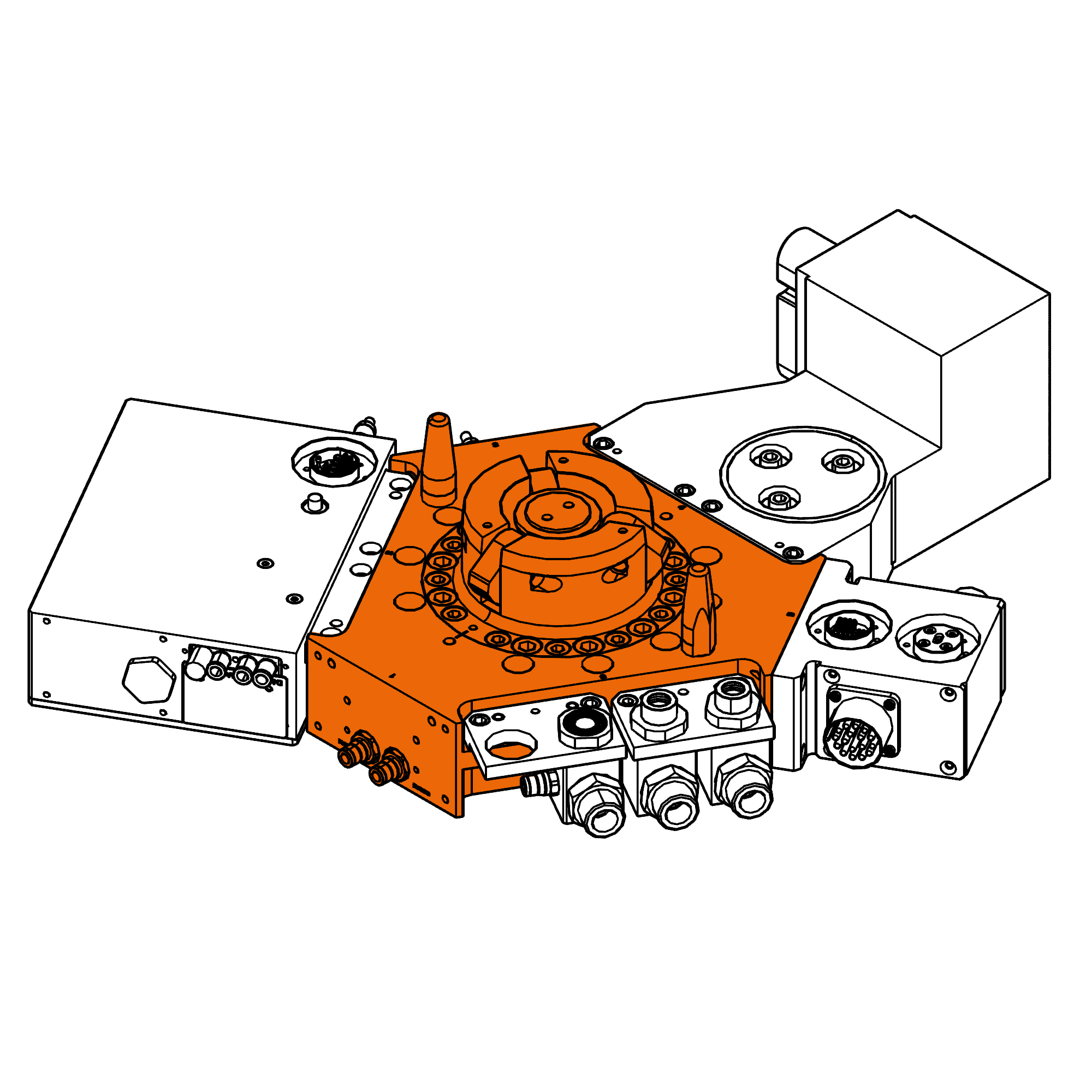

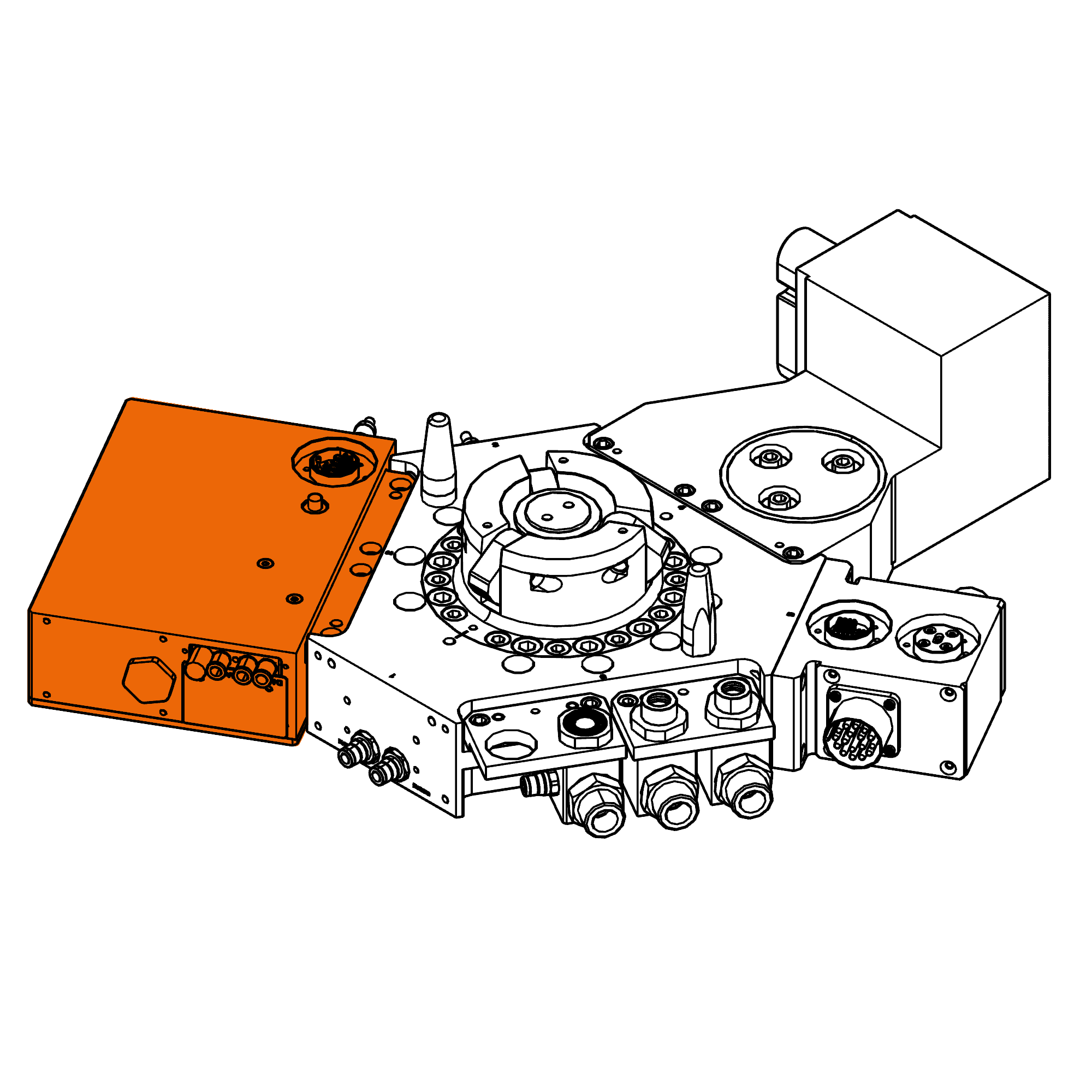

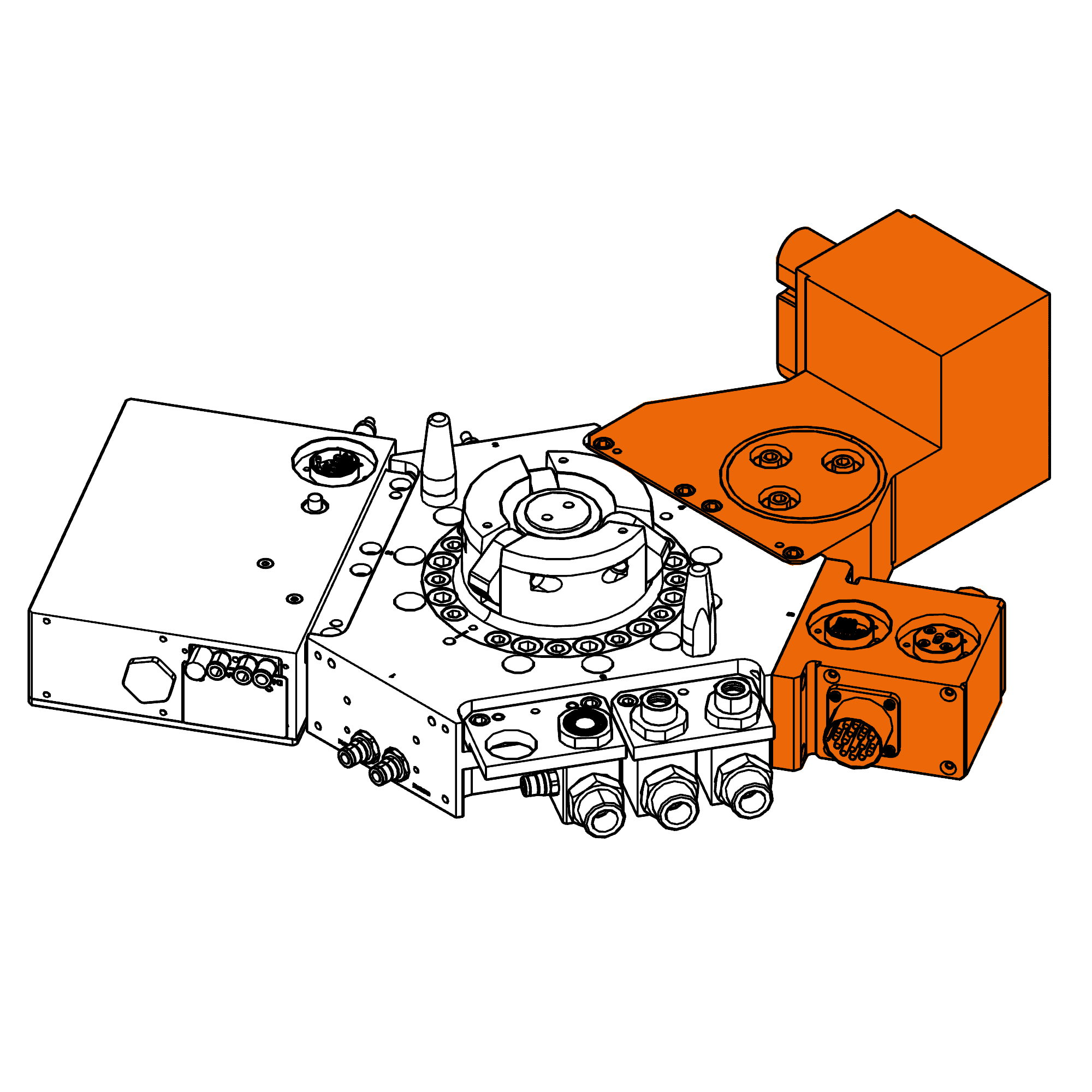

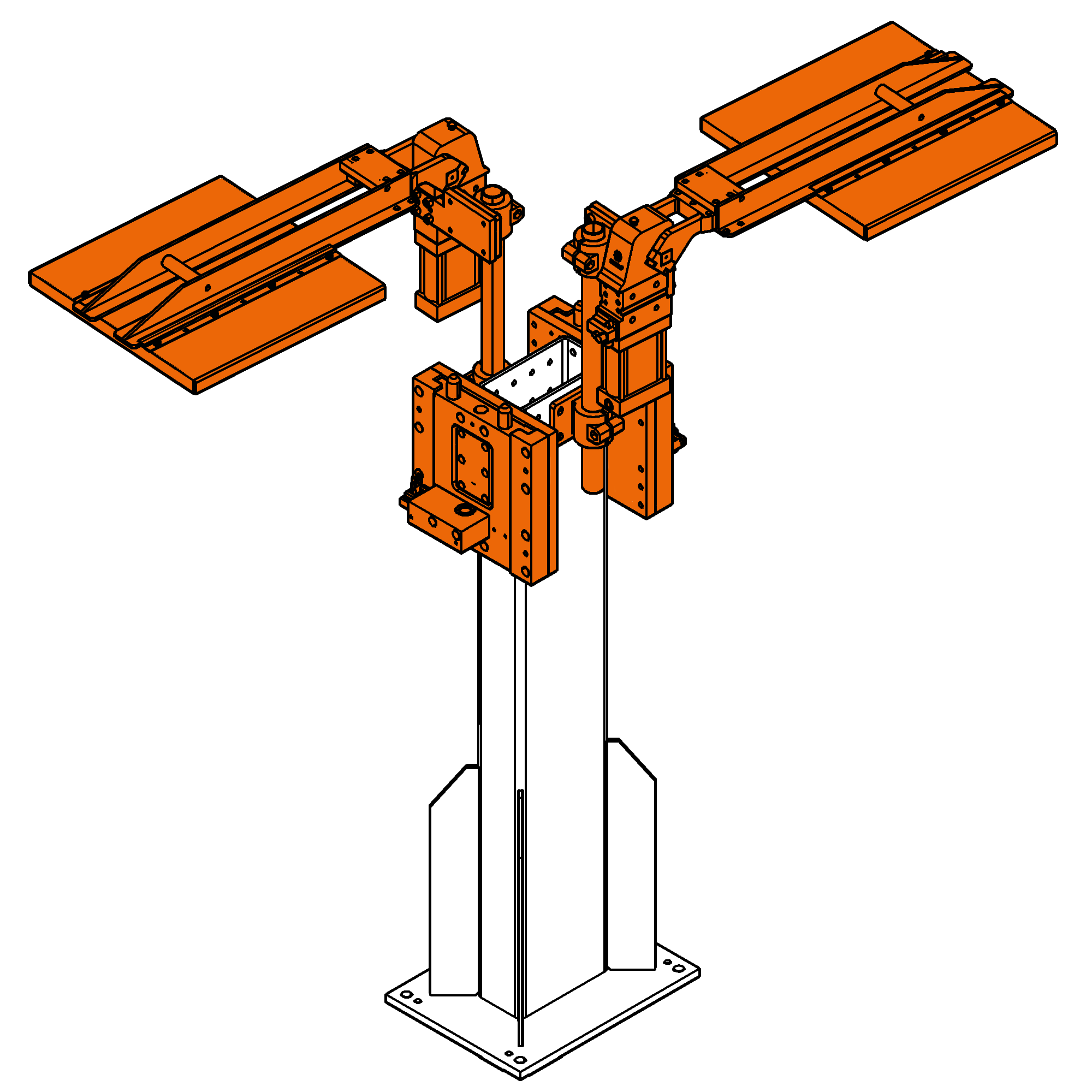

Slip ring are thus required to connect moving components such as light electronics and motors to the computer. They can be installed in different axis depending on the projector design and offer full movement capabilities while inducing low mechanical constraints. Different slip ring designs can be chosen according to projector power and features, from capsule to thru-bore slip ring to transfer light and motor power alongside motor encoders signals or DMX controls.

Electrical Features

- Motor power and control

- Automation component supply and signals (I/Os, EtherCAT, Ethernet, Profinet, CANOpen, etc.)

- Sensors (RF, digital)

- Lighting power and control (DMX)

Mechanical features

- Low friction torque

- Various mounting options

- Compact and lightweight

Interesting Options

- IP65 for outdoor application

- Integrated twisted pairs

Advantages

- Long life-time without maintenance (at least 5M rotation)

- Full movement programming capabilities

- Compact and lightweight

Benefits

- Low maintenance

- Increase projector reliability

- Low costs solution available

Facts & Figures

- With a medium speed of 10rpm a slip ring can operate at least 5 years without being replaced

- Power signals and sensors or control signals (Field bus, motor encoder, etc.) can be embedded in the same slip ring