With more than 20 years of experience in industrial processes, PES provides a safe, reliable and fast tool changing solution and this even with large and heavy EOAT. It embeds electrical and pneumatic safety loop coupled to a cam lock design that allows a repetitive and safe tool change

Our Solutions

- Bin-picking applications

- Magnetic Handling Applications

- Modular EOAT

- Destacking/Thin Sheet Application

- Collaborative robots

Brands

Our product range

Support & Services

Our Solutions

- Packaging Machines Applications

- Medical/Parmaceutical Equipment

- Hose and Cable Reel Applications

- Multimedia and Entertainement Equipment

- General Industry Equipment

- Test Benches Applications

- Harsh Environment Applications

Brands

Our Solutions

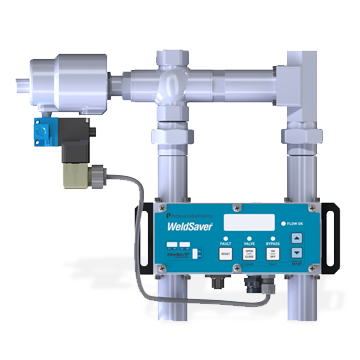

- Welding Process Applications

- Handling Applications

- Riveting/Gluing applications

- Vision or inspection applications

- Stamping line applications

Assemblies

Support & Services

Components

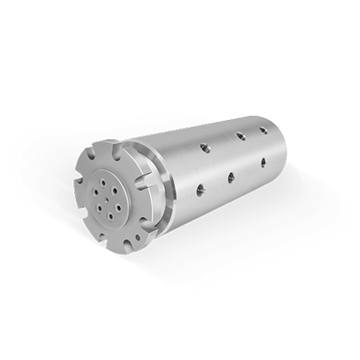

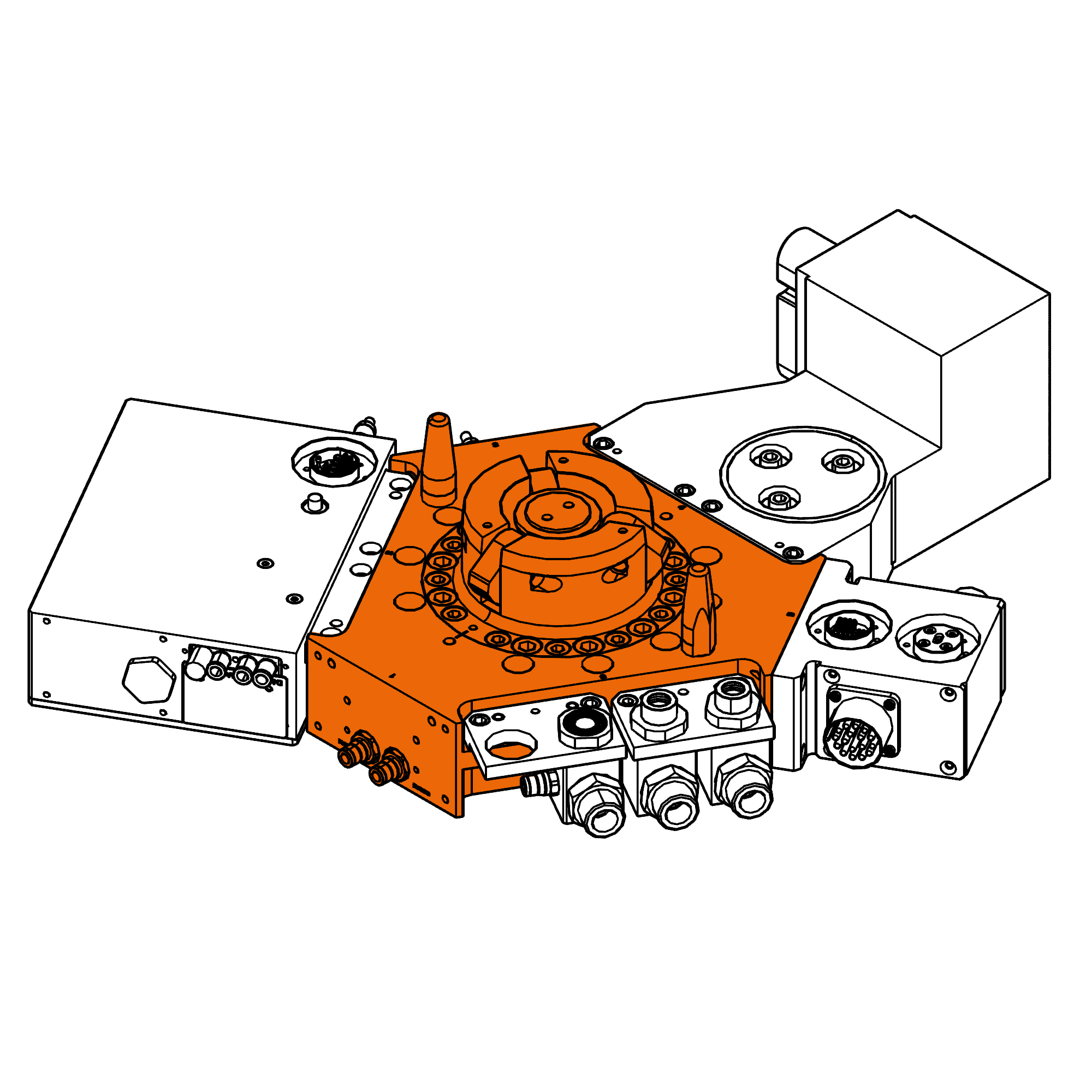

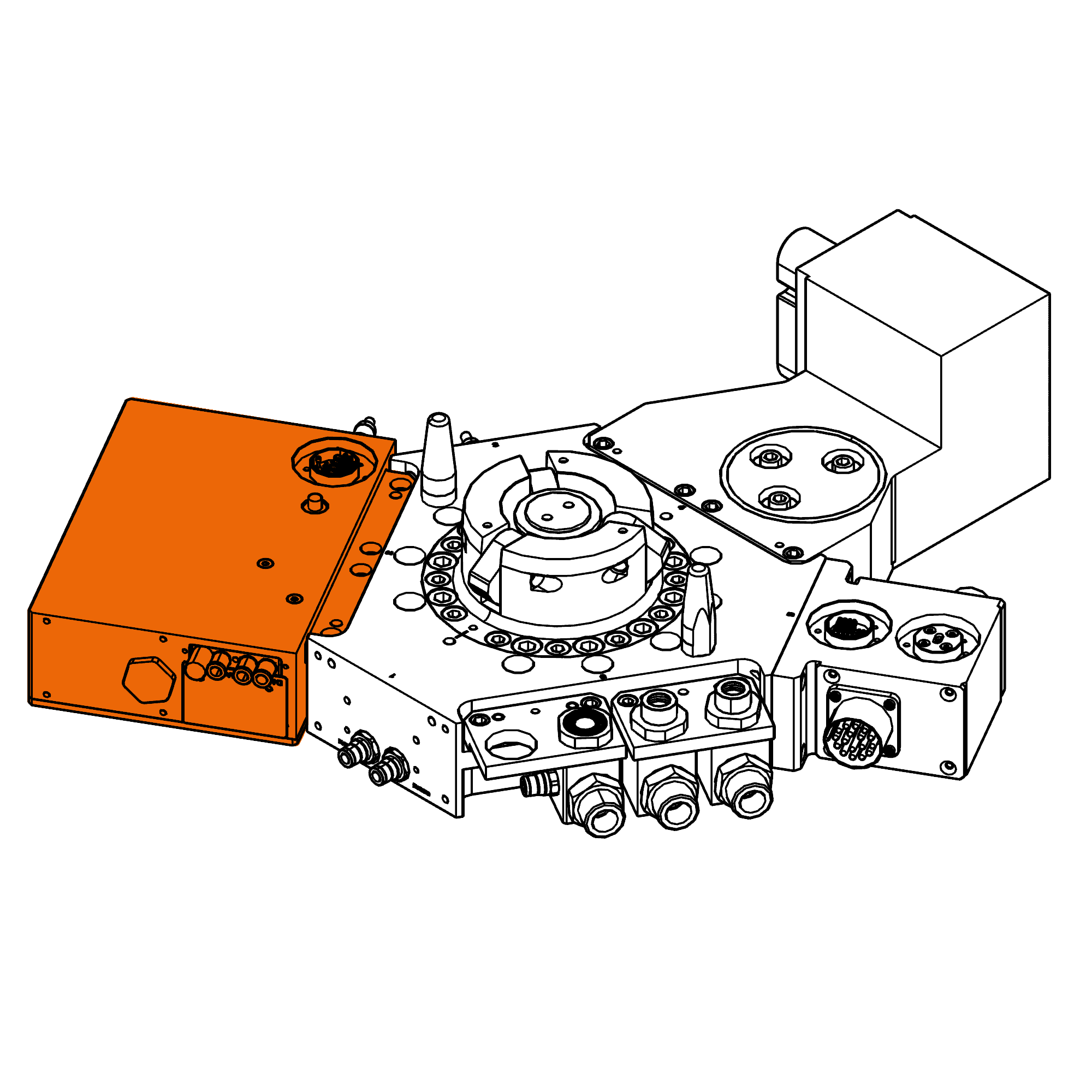

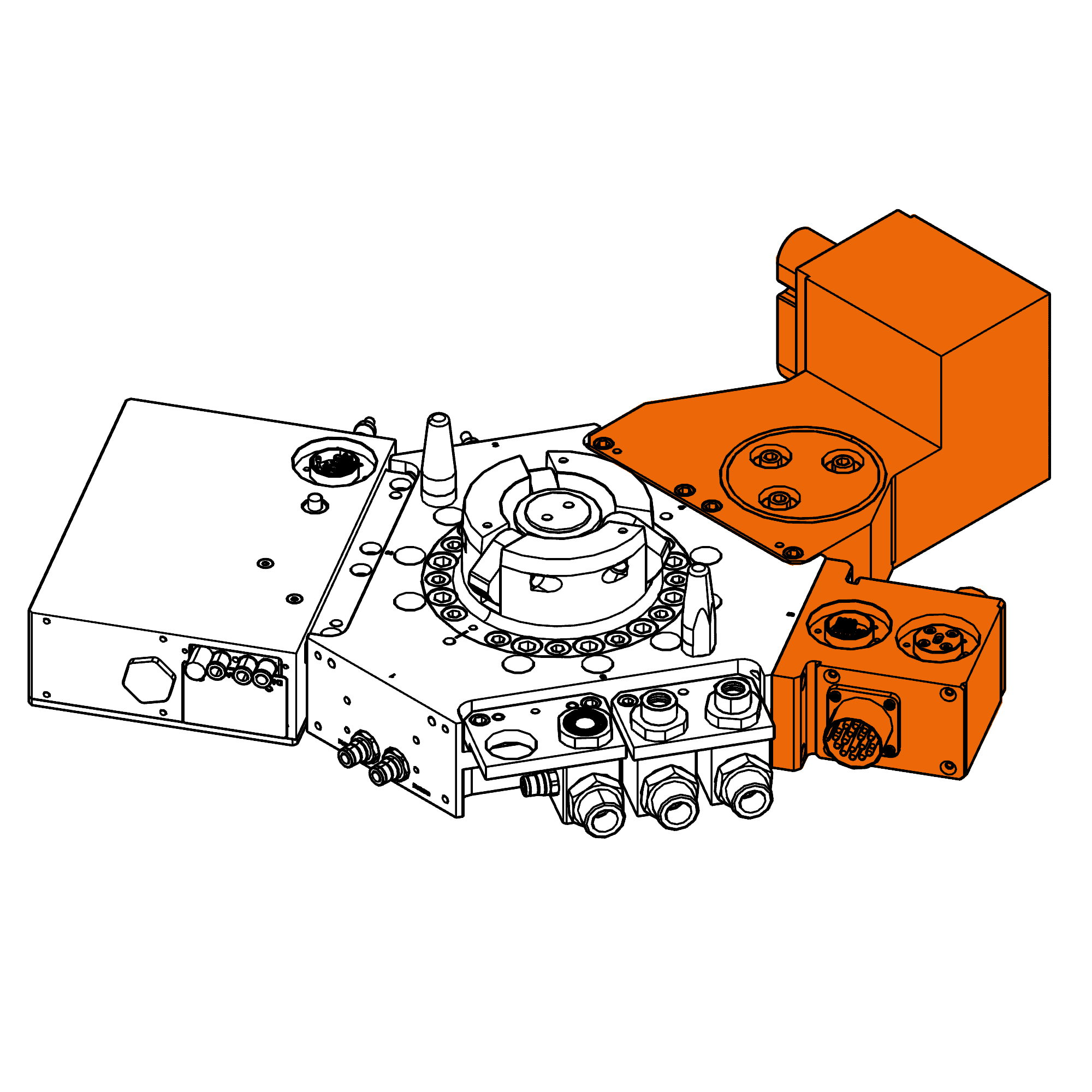

PES know-how is well-known in the automotive and other industries in creating customized modules for quick-coupling of fluids, electrical signals, and power in order to meet the robot tool needs.

We also developed specific docking stations for welding guns that include a protective cover to prevent pollution or dirt. This station also integrates 3-axis compliance that assures a tool docking and picking quality whatever the material wear and this within minimum cycle time.

Advantages

Benefits

Facts & Figures

Related industries

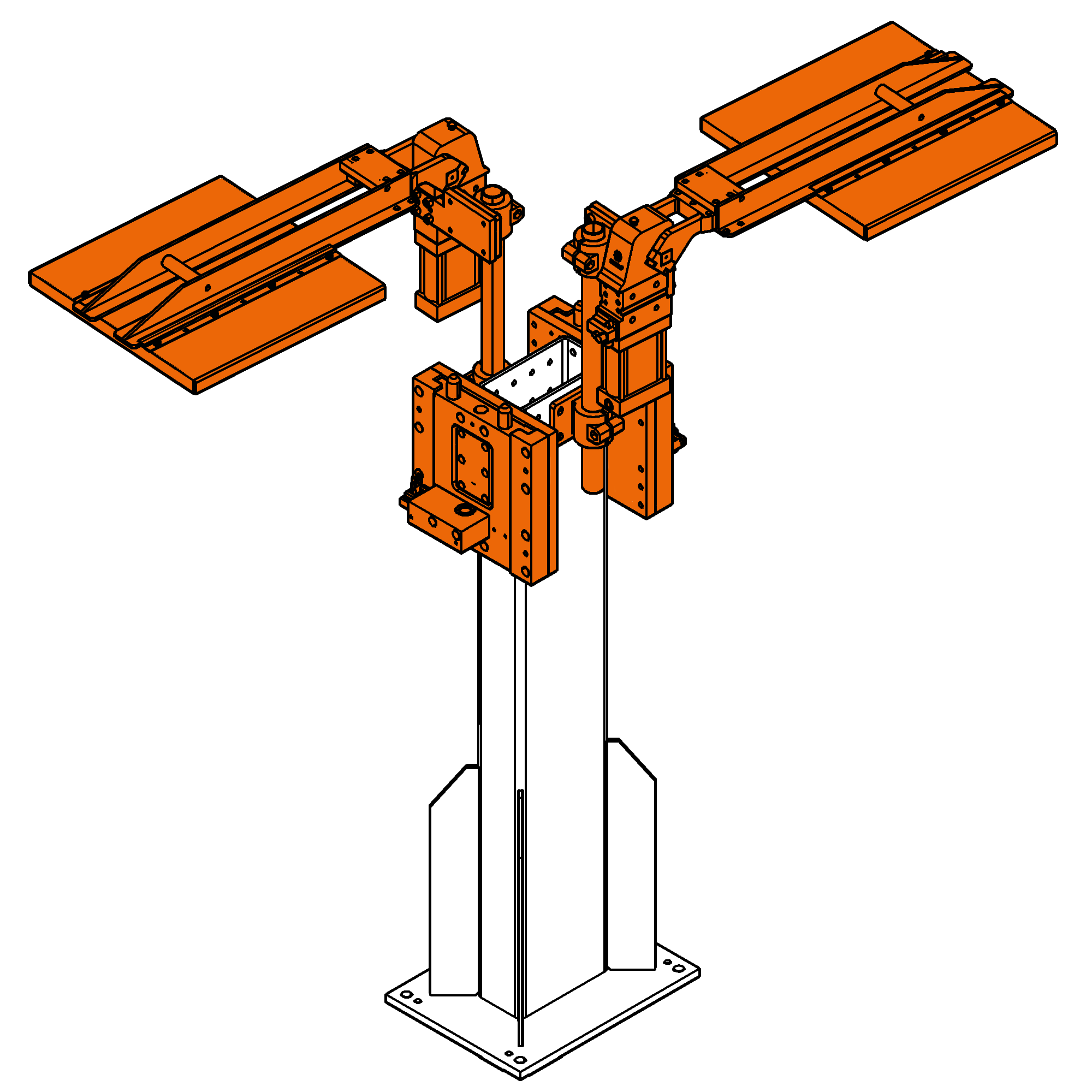

Stamping lines robots have to be lightweight to move fast and they generally handle large EOAT. Those large EOAT's have to be stored on docking stations when you use a tool changer and storing them horizontally can rapidly tend to take up large floor space areas. PES has developed the perfect tool changer solution that gives an answer to both issues.

Advantages

Benefits

Facts & Figures

Related industries

Those operations require special tooling that needs to be accurately handled and monitored with dedicated sensors in order to ensure repeatability. PES has already implemented tool changing systems for such special operations. Our custom module design and manufacturing capabilities help us to adapt to any kind of equipment that is present on the robot end-of-arm while the cam lock mechanism with integrated wear compensation ensure the accuracy and repeatability that riveting or gluing applications need.

Advantages

Benefits

Facts & Figures

Related industries

When using a tool changer with tools that embed such cameras, the major challenge is to transfer the high data rate video signal through the tool changer quick connection.

From standard 100Base-TX Ethernet to GigE Vision application, PES always provides the proper electrical interface to meet the communication standard requirement.

Sometimes we also integrate contact redundancy for increased availability of the video link.