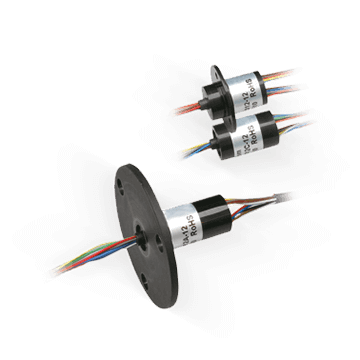

Reliable Electrical Quick Connections for High-Data Rate Video Signals

Industrial vision applications have been increasingly introduced in factories for the last past years.

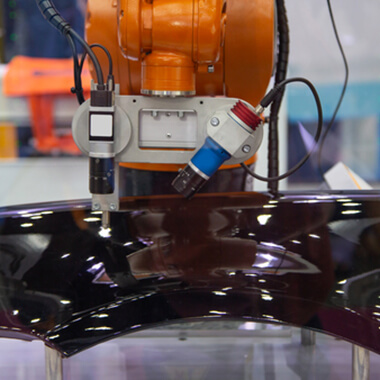

Object recognition applications enhancing automated verification tasks are now common industrial tools and there are still new applications for those cameras. Those are now sufficiently robust and compact to be embedded on robot End-of-Arm. In this specific case, they are often used to measure or correct the robot path dynamically.

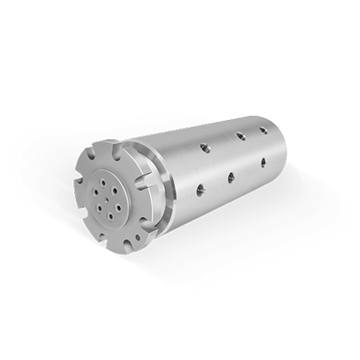

When using a tool changer with tools that embed such cameras, the major challenge is to transfer the high data rate video signal through the tool changer quick connection.

From standard 100Base-TX Ethernet to GigE Vision application, PES always provides the proper electrical interface to meet the communication standard requirement.

Sometimes we also integrate contact redundancy for increased availability of the video link.

All of our Fieldbus or vision interfaces are certified regarding the corresponding communication standard. Obviously, this video link can be embedded on the tool changer as well as other electrical or fluid interfaces to support other tools functions.

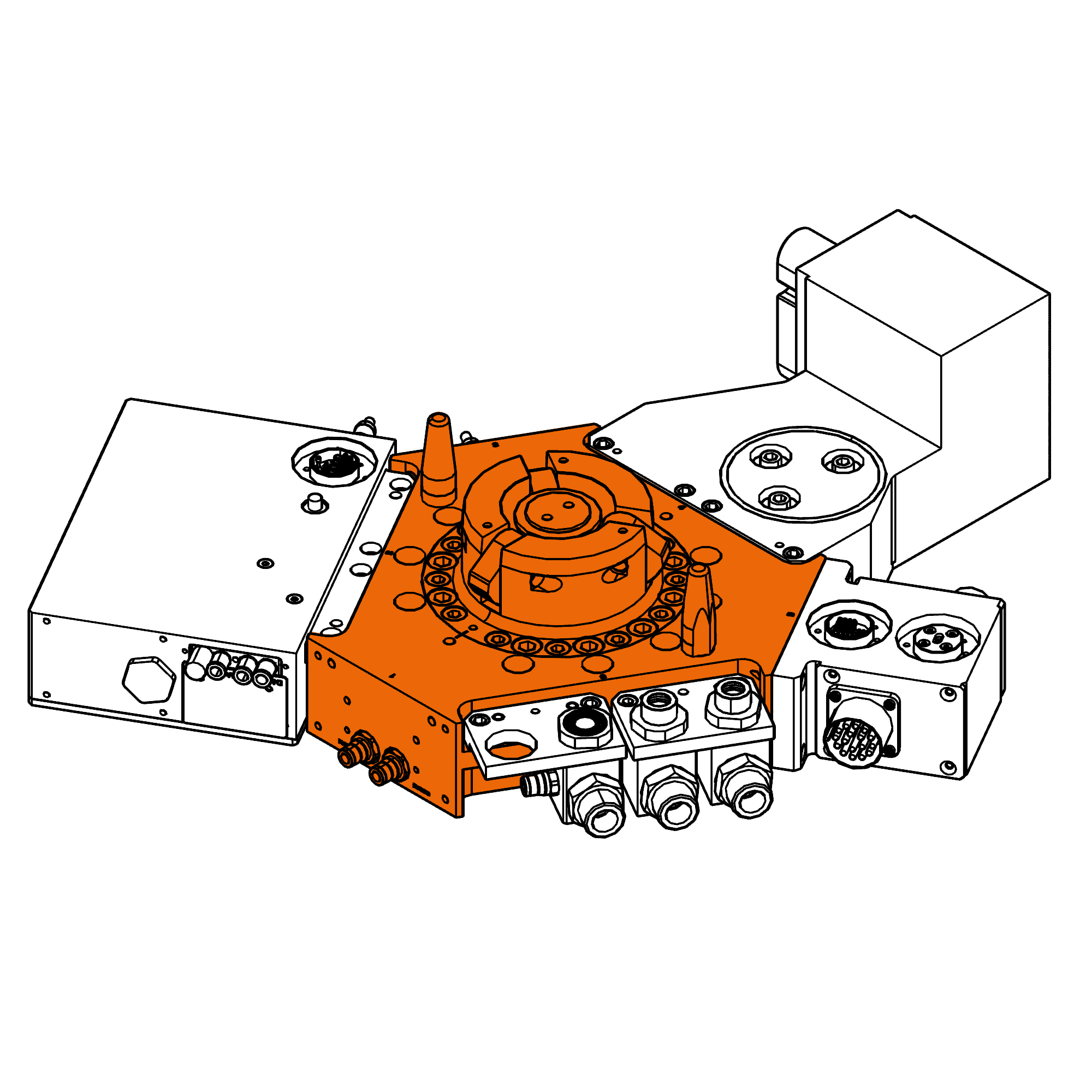

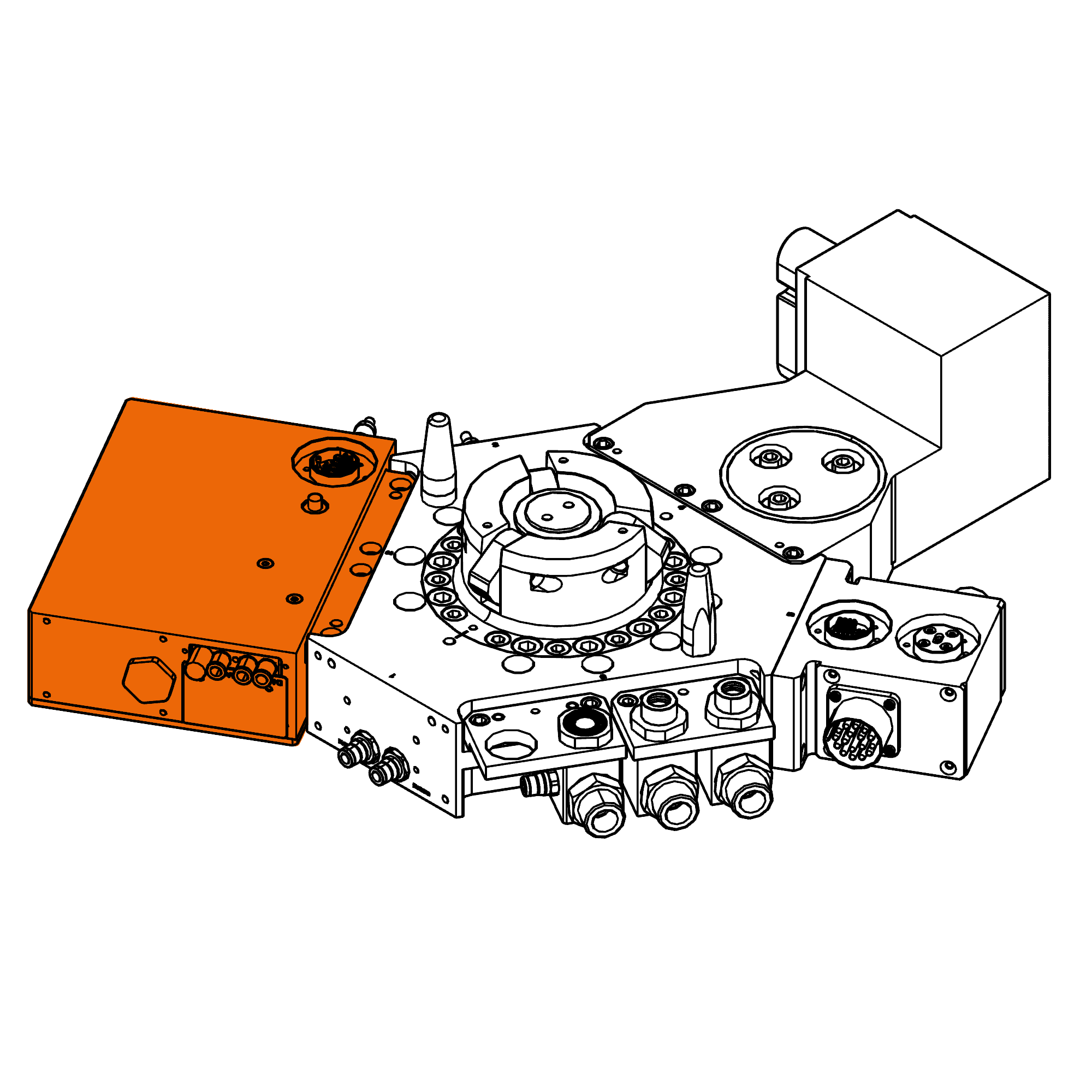

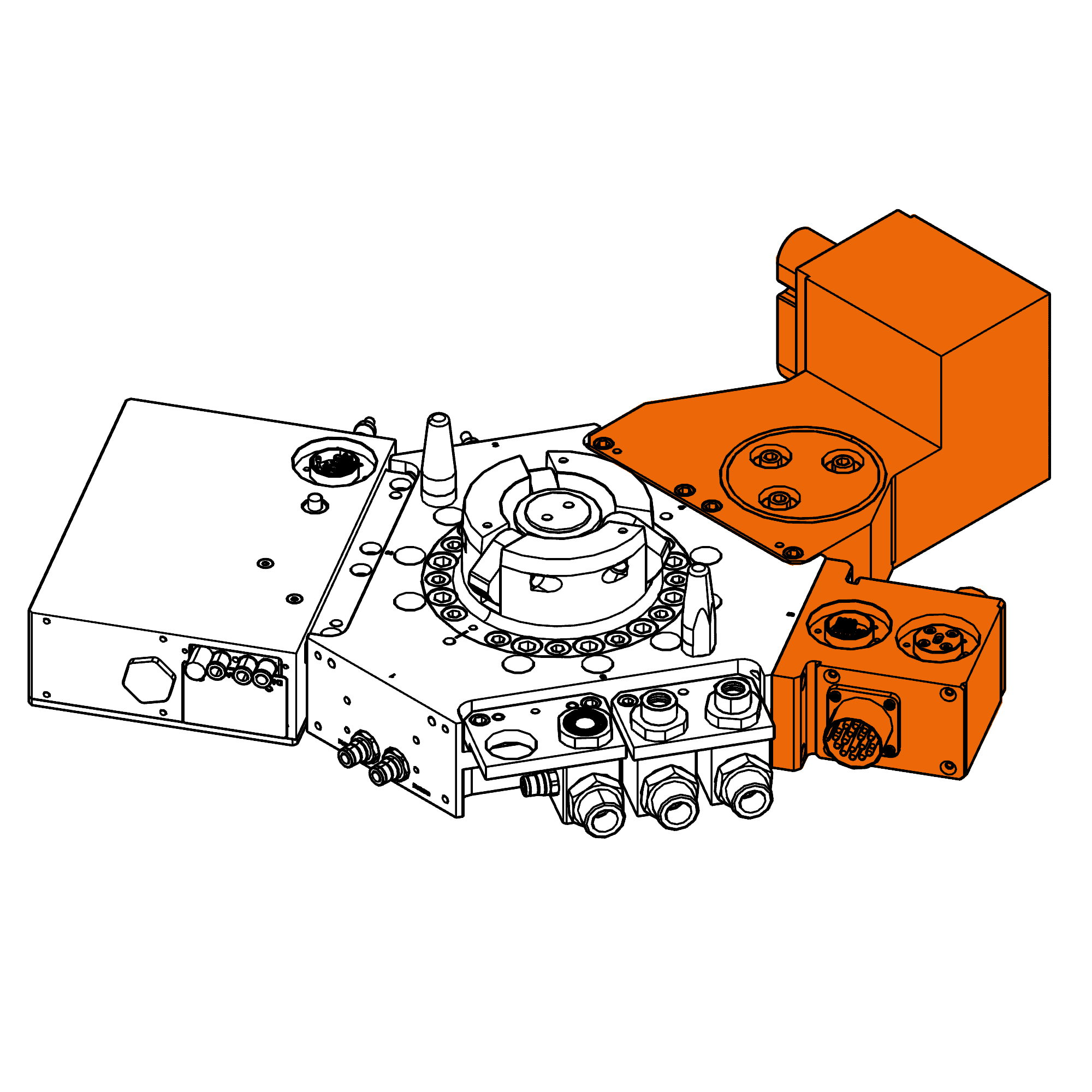

Electrical Features

- Quick connection of motors (power and control)

- Quick connection of Field Buses or discrete I/Os

- Quick connection for video signal

- Tool presence and docking monitoring

- Tool changer status control and monitoring through discrete I/Os or Fieldbus

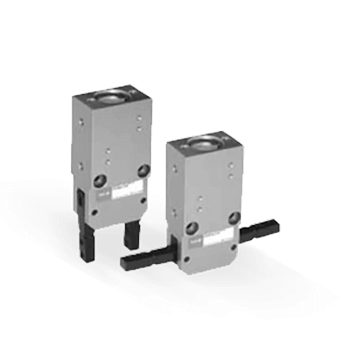

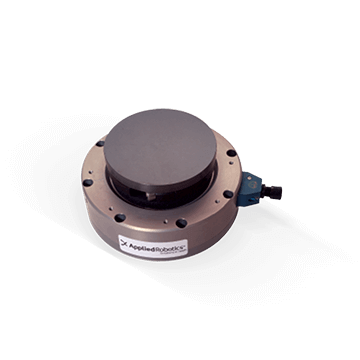

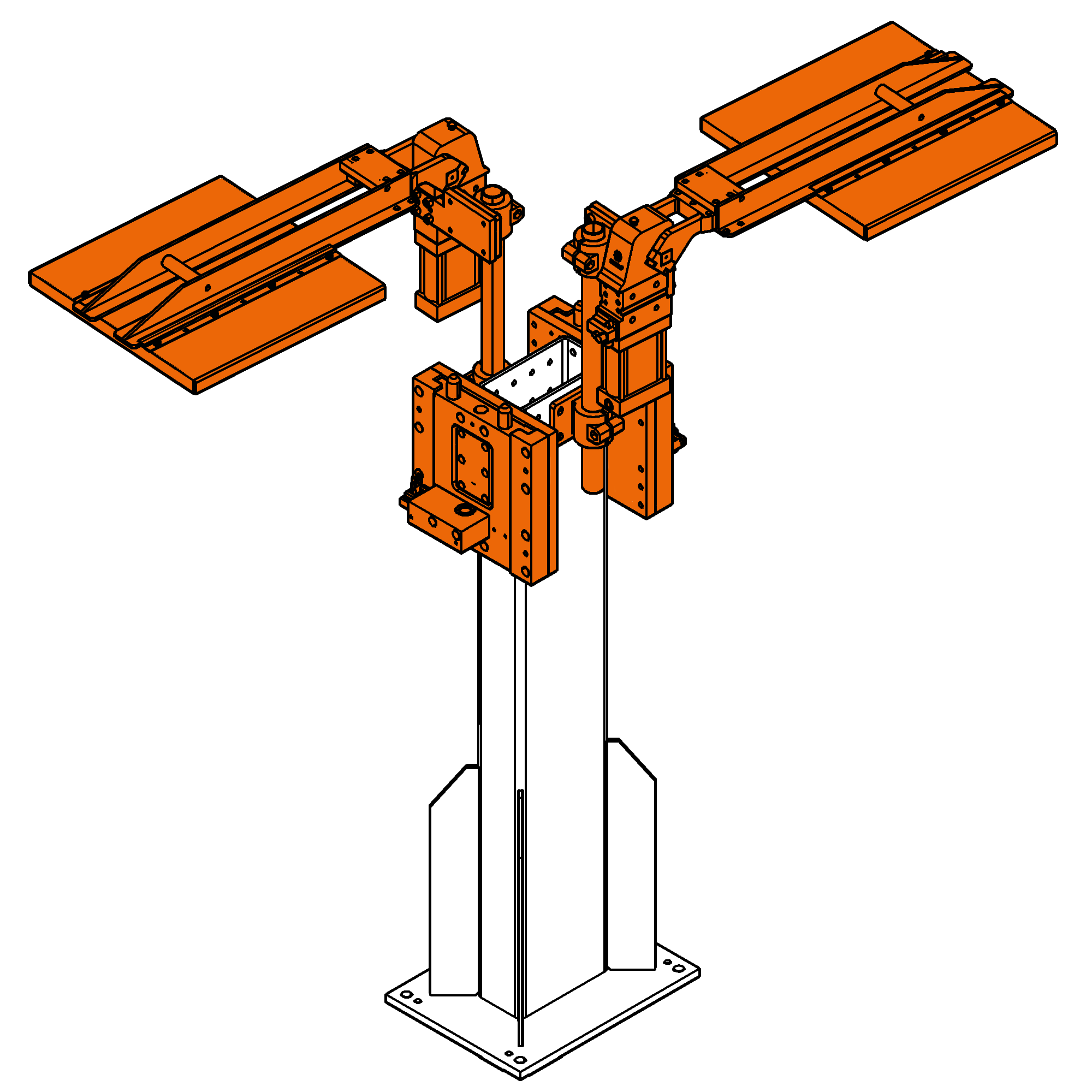

Mechanical Features

- Cam lock mechanism with integrated wear compensation

- Tough design for payloads up to 800kg and more

- Custom robot interface available

Interesting Options

- Tool coding

- Docking station with a compliant fixture

- Tool protection cover for dusty environments

- Contact redundancy for higher availability

Advantages

- Manual or software unlocking nearly impossible once locked and under safety loop monitoring

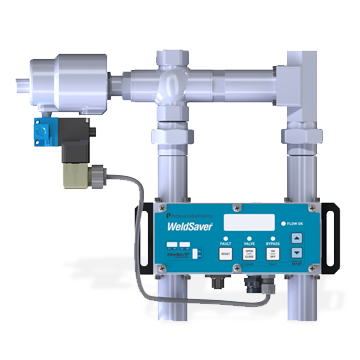

- Continuous tool changer status monitoring (air pressure, sensors, etc.)

- Minimal cycle time, reliable and repeatable

- Certified communication link

Benefits

- Enhance robot and production line capabilities

- Mitigate energy consumption (no energy needed for a docked tool)

- Reduce integration costs

Facts & Figures

- With good integration, tool change can be performed in less than 5 seconds

- Cam locking mechanism can outreach 5 millions of operation cycles

- PES Tool Changing Solution complies with Level-D safety performance level requirements

- PES is a leading supplier of tool changing systems in the automotive industry worldwide for more than 20 years with hundreds of units in operation