Safe and Flexible Solution to Enhance Production Tool Capabilities

Large industrial investements are most of the time supported by long-term and optimized production plans.

For example, a stamping press line has to be used as much as possible and so it has to be flexible to adapt itself to production needs and this while minimizing cycle time for tooling adaptation operations.

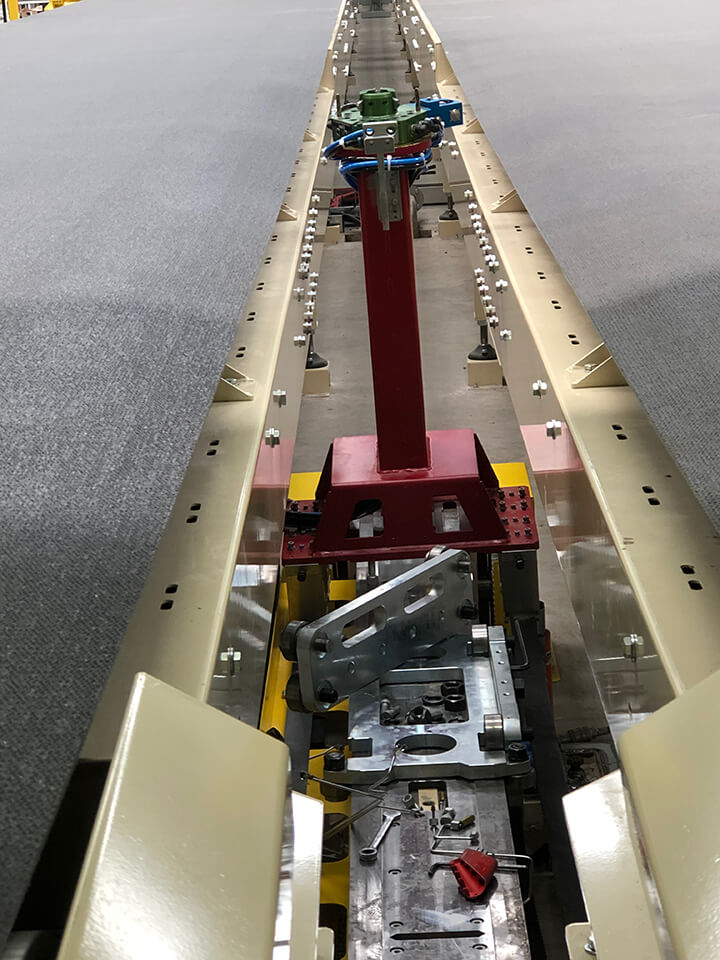

As a leading tool changing solutions provider, PES has developped a robot tool changer-based shuttle solution to increase stamping press line adaptability.

The E125LP-based shuttle solution solution is splitted in two sub-systems : the first is a standard tool changer set mounted on a robot (see our Tool Change Solution for Stamping Process); the second is a similar tool changer sub-assembly that aims at being mobile, transported by a linear axis, an autonomous vehicle or even another robot.

Tooling can then be coupled with two mobile devices, this can be usefull to adapt a conveyor to production flow or automate gripper logistics by installing tool docking station on AGV or even transfer tool from one robot to another to save docking operation cycle time.

Obviously, those solutions comes with PES Level-D performance safety and wear compensation tool coupling mechanism.

Electrical Features

- Axis-3 control box: power and field bus connections (+ tool changer and pneumatic control components)

- Tool changer: discrete I/Os and 8 integrated pneumatic ports

- Tool presence and docking monitoring

- Tool changer status control and monitoring through discrete I/Os or Fieldbus

Mechanical Features

- Cam lock mechanism with integrated wear compensation (each side)

- Tough design for payloads up to 200kg (Epsilon 125) and 300kg (Sigma 3)

- Custom robot interface available

Interesting Options

- Vertical docking station

- RFID docking system with communication through the docking station

Advantages

- Epsilon 125 based : lightweight and compact, 8 integrated air connections

- Simple installation and maximum flexibility

- Transform your fixed tool docking station into a safe and mobile solution

- Proven-in-Use turnkey functional package

Benefits

- No need to increase robot payload

- Increased performance/cost ratio

- Production line adaptability enhanced

- Low maintenance costs

- Limited integration costs

- Reduced store area

Facts & Figures

- With a good integration, tool change can be performed in less than 5 seconds

- Cam locking mechanism can outreach 5 millions of operation cycles

- PES Tool Changing Solution complies with Level-D safety performance level requirements

- PES is a leading supplier of tool changing systems in the automotive industry worldwide for more than 20 years with hundreds of units in operation